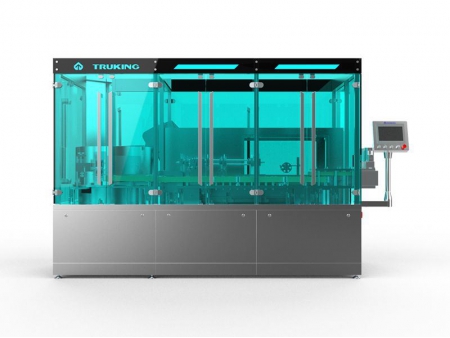

Automatic Bottle Unscrambler,LP-200

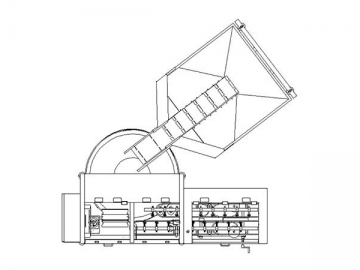

The LP-200 automatic bottle unscrambler contains a bottle elevator, rejector, and arranger as well as an electrical cabinet. Bottles in any order placed on the bottle elevator will be conveyed and arranged to stand upright, ready for washing and filling. An important part of the bottle packaging production line, this unscrambling machine saves significant time and labor.

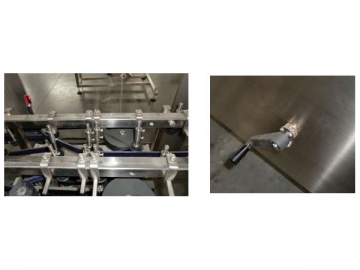

Inside part of machine:

Main performance parameters:

1. Bottle Diameter:Φ45-90mm

2. Bottle Height:80-240mm

3. Speed: ≤200bottle/min.

4. Air Pressure: 0.5~0.7MPa

5. Power: 2 KW

6. Power Source: AC220V, 50Hz

7. Bottle-Elevator Dimensions: 2200 x 1000 x 1900(L x W x H) mm

8. Unscrambler Dimensions: 2600 x 1450 x 1370(L x W x H) mm

9. Maximum Weight:about 1250Kg

Features:

1. At 3 meters long and lightweight, the unscrambler is easy to operate and adjust to fit parameters.

2. Can process a wide range of bottle sizes from 50-1000ml simply by adjusting the belt in the bottle hopper.

3. Stable with a 100% qualified rate.

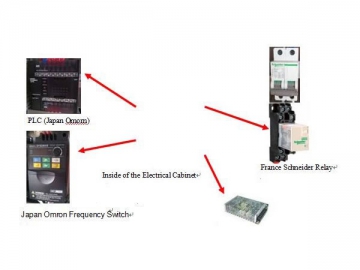

4. Imported electrical components ensure a long and reliable service life.

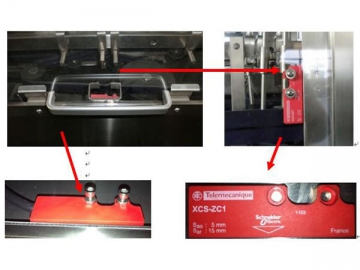

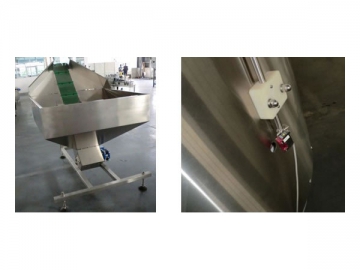

5. A sensor on the glass cover allows the machine to operate only when the cover is closed for safety.

6. An automatic bottle elevating function senses when there are enough bottles on the rotary plate before conveying to the next stage.

7. Sensors stop the unscrambling machine automatically if there is a jam and start when it is cleared.

| No. | Name | Origin | Brand |

| 1 | PLC | Japan | Omron |

| 2 | Frequency Converter | Japan | Omron |

| 3 | Magnetic Switch | France | Schneider |

| 4 | Sensor | Japan | OMPEX |

| 5 | Power Switch | France | Schneider |

| 6 | Cylinder | Korea or Taiwan |