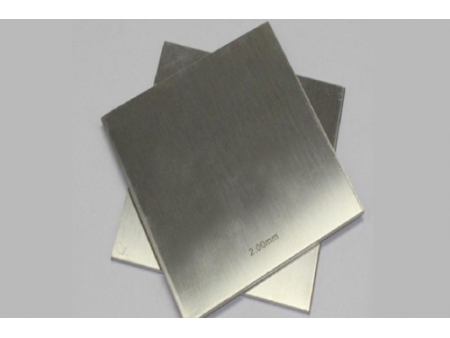

201 202 Stainless Steel

Request a Quote

Features

The GH2132 alloy is a type of heat resistant alloy with high strength and outstanding oxidation resistance. When the temperature is under 650℃ it features high yield strength, endurance, and creep strength. At the same time it offers good plasticity and decent solderability.

Specification

| Grade | 201,202 |

| Standard | ASTM A240, A666 |

| Thickness | 0.2-10.0mm |

| Width | 600mm min |

| Length | 2000mm-8000mm or as customers' request |

| Surface finish | NO1,No.4,2B, BA, 6K, 8K, Hair Line with PVC |

Chemical Composition

| Grade | C | Si | Mn | P≤ | S≤ | Cr | Mo | Ni | Other |

| 201 (mid copper) | ≤0.15 | ≤1.00 | 10-11 | 0.045 | 0.03 | 12-14 | - | 0.8-1.0 | Cu 0.8-1.0 |

| 201 (high copper) | ≤0.15 | ≤1.00 | 9.5-10 | 0.04 | 0.03 | 13-15 | - | 1.0-1.2 | Cu 1.4-1.6 |

| 202 | ≤0.15 | ≤1.00 | 7.5-10. | 0.06 | 0.03 | 17-19 | - | 4.0 | N≤0.25 |

Mechanical properties

| Grade | YS(Mpa) ≥ | TS (Mpa) ≥ | El (%)≥ | Hardness(HV) ≤ |

| 201 (mid copper) | 200 | 520 | 25 | 210 |

| 201 (high copper) | 200 | 520 | 35 | 210 |

| 202 | 200 | 590 | 40 | 180 |

- Applications

- Turbine disks, stamping and welded parts as well as fasteners that need to maintain their stability at temperatures up to 700℃

- GH2132 alloy is often applied for aircraft engine components and gas turbine components, such as turbine blades, afterburners and so on

Other Alloy Materials