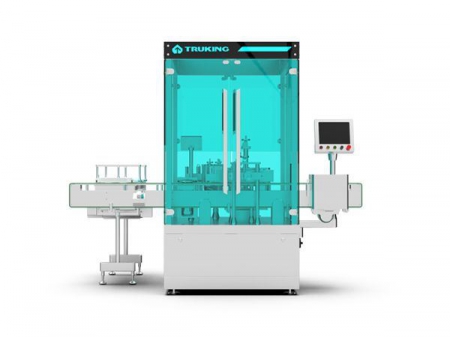

AS-C01 Wrap-around Labeling Machine

Request a Quote

The wra¬p-around labeling machine is designed for the application of partial or full wrap labels on round bottles and cylindrical containers with diameters ranging from 25mm to 100mm.

The machine has a labeling speed of 120pcs/min.

Applications

- Applicable labels: self-adhesive label, self-adhesive film, electronic supervision code, bar code, etc.

- Applicable products: products with round surfaces

- Applicable industries: food, pharmaceutical, cosmetics, daily chemical, electronics, hardware, plastic, etc.

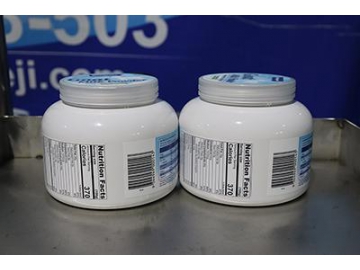

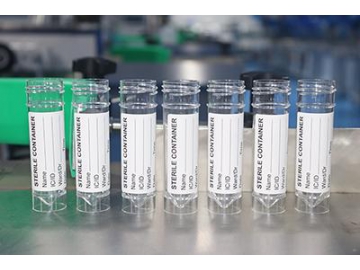

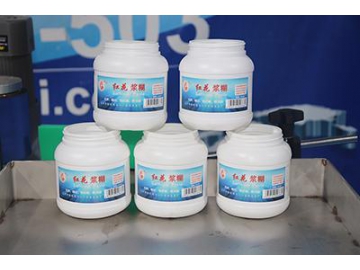

Samples

Options

- Optional automatic rotary bottle unscrambler

- The wra¬p-around labeling machine can be integrated in your production line to realize automatic container feeding to maximize output and label quality.

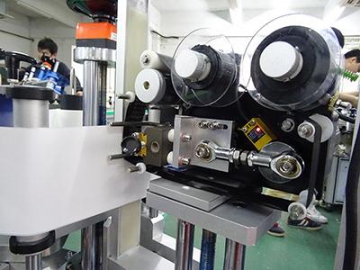

- Ribbon printer is optional.

- The machine can print the production date and batch number in-line to simplify the packaging procedures and improve overall production efficiency.

Specification

| Model | AS-C01 |

| Label stop accuracy | ±1mm |

| Production speed | 30-120 pcs/min |

| Product diameter | φ25mm~φ100mm |

| Product height | 25mm~300mm |

| Label length | 20mm~310mm |

| Label roll inside diameter | Φ76mm |

| Label roll outside diameter | Φ280mm |

| Dimensions (length x width x height) | 1950mm x 1100mm x 1280mm |

| Weight | 185Kg |

Details of Wrap-Around Labeling System

Photoelectric sensor:

Photoelectric sensor:

High precision and reliable Sick brand photoelectric sensor Touch screen:

Touch screen:

It is controlled by PLC. The interface is convenient to use. With just a tap of its touch screen, you can easily access various functions and parameters for your product needs. Coding machine:

Coding machine:

It can print information such as batch numbers on the labels during the labeling process. Bottle dividing mechanism:

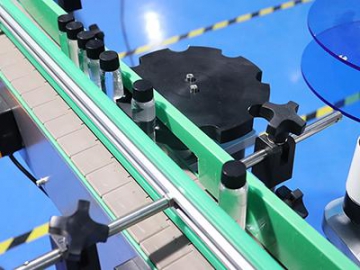

Bottle dividing mechanism:

It controls the speed of the motor to create appropriate gaps among the bottles to ensure each bottle has sufficient labeling time. Smoothing device:

Smoothing device:

It guarantees perfect label adhesion to the surface of the container and eliminates bubbles by means of exerting pressure on either side of the container.- Label adjusting mechanism:

Label position, height, and angle can be adjusted by the label adjusting mechanism. It enables the label to be applied to bottles of different shapes with high accuracy.

Related products

Send Message

Most Recent

More

Other Products

Videos