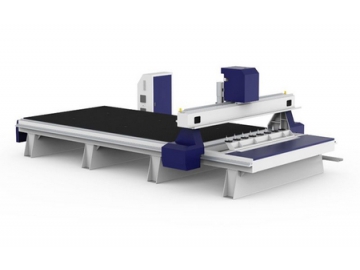

SD-M25 ATC Woodworking Process Center

SD-M25

Feature

1. The ATC spindle comes with a CLOAK tools storeroom.

2. The ATC woodworking process center is equipped with a Taiwan H30 linearguide rail with high precision.

3. YASKAWA SERVO motor is utilized for equipment driving.

4. LNC / SYNTEC control system

5. Designed with 8 separate vacuum zone, the ATCwoodworking process center can fix workpiece by suction force.

Technical Parameters of SD-M25 ATC Woodworking Process Center

| X Y working area | 52"×100"(1300×2500mm) |

| Z working area | 8"(200mm) |

| Table size | 60"×120"(1480×3000mm) |

| Max speed | 50m/min(1400inch/min) |

| Drive on Z axis | Ballscrew and bearings |

| Drive on X,Y axis | Precision rack & Pinion, gear drive |

| Spindle | 5.5kw water cooling spindle |

| Inverter power | AC380V/60HZ, 3-phase |

| Speed of spindle | 24000rpm |

| Motor | Servo motor |

| Working precision | 0.005mm |

| Repositioning accuracy | 0.025mm |

| Commands | G code, plt, U00, mmg. |

| Power(not include spindle) | 3kw |

| Operating system | Windows98/2000/xp |

| Collets | 3.175mm, 4mm, 6mm, 8mm, 12.7mm |

| Controller | TAIWAN LNC/SYNTEC control system |

| Design software | UcancamV9/TYPE3/ARTCAM |

| Weight, CBM | 1800KGS, 15CBM |

Construction

The ATC woodworking process center is composed of a vacuum table, vacuumpump, dust cover, dust collector system with 6 zones separately controlled, airpump, transformer, oiling system, 8 auto tools changer, liquid filter,20 cutters( φ6, φ12.7), and 5 collets.

As an ATC woodworking process center manufacturer based in