CNC Tappng Center CNC Machining Center (Precision Machining)

Request a Quote

CNC machining center can operate drilling, tapping and milling. Its characteristic is capable to perform the tapping of small diameter holes. This CNC machining center has a maximum spindle speed of 24000rpm, meeting the machining requirements of all kinds of precision parts. But it is not suitable to process steel materials. And if you have such demands, we can recommend other CNC machining centers for you.

CNC machining center produced by Tying CNC

- X-axis travel: 500mm

Y-axis travel: 400mm

Z-axis travel: 300mm

Positioning accuracy: ±0.005/300mm

Maximum weight on table: 300kg

Spindle speed: direct drive, 12000rpm -

- XX-axis travel:600mm

Y-axis travel:400mm

Z-axis travel:300mm

Positioning accuracy:±0.005/300mm

Maximum weight on table:350kg

Spindle speed: direct drive, 15000/20000rpm

- X-axis travel:1050mm

Y-axis travel:500mm

Z-axis travel:320mm

Positioning accuracy:0.008mm

Maximum weight on table:300kg

Spindle speed: 50-20000(24000)rpm

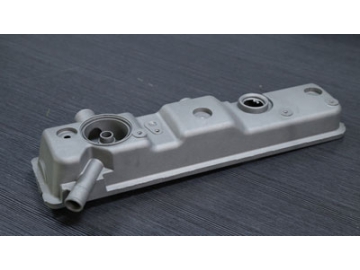

Samples machined by CNC machining center

Clock workpiece machined by CNC machine

Clock workpiece machined by CNC machine Engineering plastic workpiece processed by CNC machining center

Engineering plastic workpiece processed by CNC machining center

- The three axes of this CNC machining center adopt linear guideway with a feed speed of 48 m / min. The machining speed is fast and the machining time is saved.

- Due to the large span, its base is supported by six supporting points to ensure the stability of the whole machine during the processing.

- The spindle is directly driven by a AC servo motor to enable the spindle of low inertia and good stability.

- The tool storage changes tools quickly and precisely, thus saving processing time.

- The symmetric structure design of the spindle helps to reduce temperature difference and thermal deformation.

- When changing tools, the spindle has a tool release design to avoid bearing directly and extend its service life.

- Spindle adopts a large axis diameter design of 100nm, which can strengthen its cutting rigidity.

- The control system equips a synchronous motion tool changer to allow for quick and stable tool change function.

As for these parts, control system can be changed according to customer requirements. And our tool storage can hold much more tools. For detailed information please click the corresponding .

Related products

Send Message

Most Recent

More

Other Products

Videos