LW Horizontal Decanter Centrifuges

LW Horizontal Decanter Centrifuges

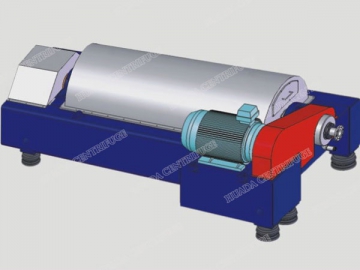

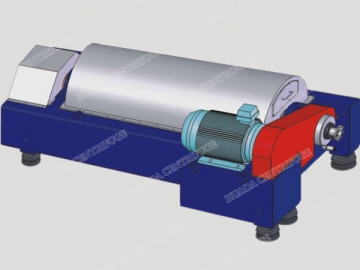

LW Horizontal Decanter CentrifugesLW horizontal decanter centrifuges feature continuous feeding and discharging. This chemical separation equipment has been applied to two-phase (solid-liquid) and three-phase (solid-liquid-liquid) slurries separation in industries of chemicals, pharmaceutics, environment protection, as well as mining and food, etc.

Advantage

1. This liquid clarifying device adopts horizontal design which balances the layout of electric motor and bowl. As a result, outstanding operation stability generates minimized vibration.

2. Dual electric motor control enables stepless speed adjustment on bowl and spiral components.

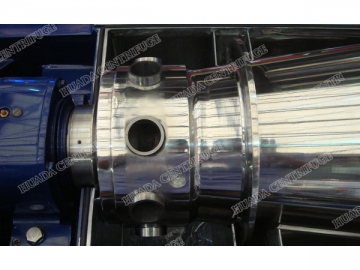

3. Scroll conveyor flight inside this continuous centrifuge is painted by abrasion resistant alloy or welded by hard alloy. Moreover, main components on our horizontal decanter centrifuge, such as rotating bowl and spiral parts, are made from corrosion resistant stainless steel or dual-phase steel, whereby offering exceptional speed limits and separation ratio.

4. Our mud dewatering equipment comes with three options including cycloidal gear, planetary gear and hydraulic differential, resulting in large range of differential adjustment. Therefore, this industrial centrifuge can be applied to diverse solids.

5. Multiple protections are available on our horizontal decanter centrifuge to ensure operatives safety, including over-vibration protection, bearing temperature detection, screw conveyor torque protection rotating and differential speed detection, as well as nitrogen-filled explosion-proof protection, motor overload and over heat protection.

6. JG type rubber shock absorber requires no anchor bolts.

- Conveyor flight adopts ceramic or tungsten

carbide tiles - Solid outlet adopts ceramic or tungsten carbide tiles

Applications

1. Industrial and municipal wastewater treatment

2. Oil & gas drilling mud/fluid control

3. Washing, separation and dewatering of starch

4. Mycelium and zymotic fluid separation for antibiotic

5. Dewatering of soybean and wheat protein

6. Dewatering of fish power and fish meat

7. Dewatering of vinasse

8. Clarification and extraction of fruit juice

9. Separation and purification for animal and vegetable oil

10. Production and purification of olive oil, palm oil, avocado oil

11. Separation and purification for coal tar

12. Grading of kaolin and graphite

13. Grading and dewatering of dyestuff and pigment

14. Froth flotation for cleaned coal and dewatering of coal mud

15. Grading and dewatering of minerals

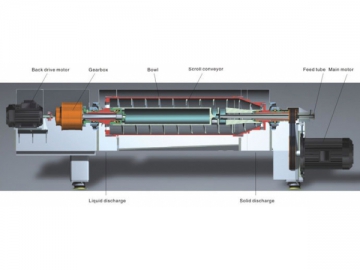

Structural Diagram for Horizontal Decanter Centrifuge

Technical Parameter of LW Horizontal Decanter Centrifuges

| Model | Bowl Dia (mm) | L/R Ratio | Max. Speed (r/min) | G-force(g) | Main Motor power (kw) | Weight (kg) | Dimension(mm) (L*W*H) |

| | 220 | 4 | 4800 | 2840 | 7.5-11 | 1000 | 1850*1200*750 |

| | 220 | 4.5 | 4300 | 2280 | 11 | 1100 | 1970*1200*750 |

| | 300 | 3.8 | 3750 | 2370 | 15 | 1500 | 2100*1300*650 |

| | 355 | 4 | 4000 | 3100 | 22 | 2020 | 3365*920*1060 |

| | 400 | 3 | 3600 | 2880 | 22 | 2200 | 2400*1650*900 |

| | 400 | 4 | 3600 | 2880 | 30 | 3000 | 3100*91650*900 |

| | 450 | 1.7 | 2500 | 1570 | 30 | 2000 | 2348*1090*943 |

| | 450 | 4 | 3500 | 3083 | 30-37 | 3500 | 4200*1090*1250 |

| | 450 | 4.5 | 3600 | 3260 | 30-37 | 37800 | 4200*1090*1250 |

| | 530 | 4 | 3200 | 3040 | 45-55 | 4200 | 4885*1230*1350 |

| | 530 | 5 | 2500 | 2150 | 37-55 | 4500 | 5050*1230*1350 |

| | 630 | 3.65 | 2500 | 2205 | 75 | 8000 | 5110*1440*1750 |

| | 720 | 3.7 | 2000 | 1600 | 110 | 12000 | 5365*3160*1510 |

| | 1000 | 3 | 1500 | 1258 | 132-160 | 16000 | 5180*2450*1950 |