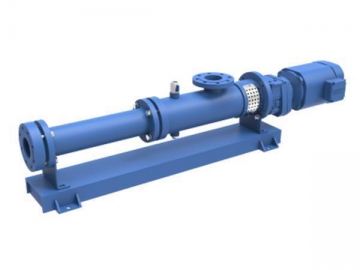

S Class Progressive Cavity Pump

Applications

The S class progressive cavity pump is designed and produced to transport any medium including water. The mediums with solid content up to 45% can also be pumped. The main pumping applications are listed below:

1. Food processing plant: delivering honey, maltose, dairy products, beverages, etc.

2. Sewage treatment plant: transport of desulphurized sewage, sludge, etc.

3. Chemical plant: transportation of ink, pigments, optical fiber ointments, etc.

Parameters

Stage: 1-12 stages

Type: single-head monoblock pump, double-head nonoblock pump

Working pressure

single-head pump: 6 bar, 12 bar, 18 bar, 24 bar, 36 bar, 48 bar, 60 bar, 72 bar

Double-head pump: 5 bar, 10 bar, 20 bar

| Model | Flow range m3/h | Speed range rpm | Motor power Kw | |

| VD015-006P02OH | 0.18~0.42 | 180-550 | 0.37 | |

| VD020-018P02OH | 0.5~1.2 | 180-550 | 0.55 | |

| VD030-056P02OH | 1.5~6 | 180~600 | 0.55~1.5 | |

| VD035-120P02OH | 3~10 | 180~550 | 0.75~3 | |

| VD040-010P02OH | 4~15 | 150~520 | 1.1~4 | |

| VD050-022P02OH | 8~25 | 150~450 | 4~7.5 | |

| VD060-038P02OH | 12~40 | 150~390 | 7.5~11 | |

| VD070-058P02OH | 15~60 | 120~350 | 11~15 | |

| VD090-106P02OH | 30 ~100 | 120~350 | 15~30 | |

| VD100-160P02OH | 35~140 | 100~300 | 15~37 | |

| VD120-240P02OH | 60~200 | 90~270 | 37~45 | |

| VD150-480P02OH | 70~270 | 60~200 | 37~55 | |

| VD170-600P02OH | 80~340 | 50~190 | 45~90 | |

Working principle

Progressive cavity pumps are positive displacement pumps which depend on the interference fit between the rotor in eccentric motion and the fixed rotor. This forms seal cavities that are disconnected from each other. Through the rotation of the rotor inside the stator, the seal cavities are moved axially from the inlet end of the pump to the outlet. This is how fluid mediums are conveyed using the seal cavities of the pump.

- Design drawing of the stator and the rotor

- Metal flexible rod universal joint

- Spring flexible rod universal joint

- Ball tooth universal joint

Rotor

The rotor of the pump is designed and machined into various geometric shapes according to the requirements of the customer. Surface hardening or vacuum heat treatment are performed on metal components. After these treatments, the hardness of the materials can reach HRC 65-67.

Stator

Material: NBR, NBRH, HNBR, EPDM and FKM are available for selection. They cover various abrasion and temperature resistances as well as working conditions.

Universal joint

We provide a variety of universal joint transmission components to choose from. There are traditional pin type and pin sleeve type universal joints, as well as food hygiene class, flexible types, ball tooth types, and cross pin type joints. They can deal with various torque transmission levels and axial loads.

Shaft seal

The shaft seals can be either packing seals or mechanical seals. The correct choice depends on the working conditions present for your application. Cooling and washing systems are available in order to extend the working life of the shaft seal.

Driving system

SEW, NORD, ABB and other high quality driving systems are available to choose from.

Weifang Subtor as a German Subtor invested company in China, offers wide range of progressive cavity pumps and components. The S class progressive cavity pump has typical applications as food pumping, sewage and sludge pumping, viscous fluid pumping, etc. A progressive cavity pump is a type of positive displacement pump, also known as eccentric screw pump. With German supported technology and rich marketing resources, Subtor provides quality PCP pumps with custom solutions for global clients.