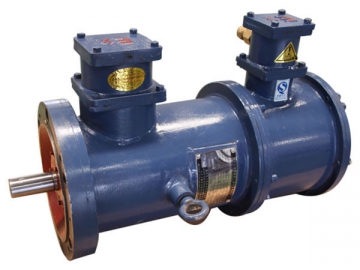

Explosion Proof Three-Phase Induction Motor

The YB2-H series of the explosion-proof three-phase induction motors is a completely enclosed fan-cooled induction motor of the squirrel-cage type. The motors are designed and manufactured according to national standards for electrical equipment in explosive working environments and are flameproof, high performing, and quiet. The squirrel cage motors drive marine machinery, such as pumps, ventilators, separators and hydraulic machines in working conditions where explosives or hazardous materials are present. The motors are in accordance with the following standards:

IEC60034 Rotating electrical machines

IEC60068 Basic environmental testing procedures

IEC60072 Dimensions and output ratings for rotating electrical machines

IEC60092 Electrical installation in ships

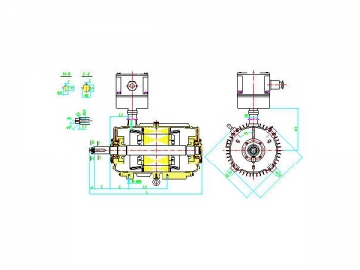

Construction

1. IP44 or IP56 (TEFC) protection

2. Cylindrical shaft extension. B3 and B35 motors with two shaft extensions are available upon request, but the second shaft extension can only transmit a rated output with direct coupling. The shaft is made of high grade steel No 45.

3. Terminal box is in full conformity with IEC publication 60034-8. Clearance between two neighboring conducting parts is not less than 8mm and all creepages is not less than 12mm. An extra terminal is provided inside the box for grounding.

Operating Conditions

Temperature of Ambient air: -20℃~ 45℃

Altitude: 0m

Relative humidity: ≤95%

Dew: exists

Salt mist: exists

Oil mist: exists

Fungus: exists

Shock: exists

Vibration: exists

Inclination and swing: ±22.5°

Rated Voltage: 380V or 440V

Rated Frequency: 50Hz or 60Hz

Connection: 3kW or Less Y,more than 3kW △

Duty Type: Continuous S1

Insulation: F

Rise of winding (resistance method): 80K

Permissible working temp of bearing: (thermometer method) 90℃

Mounting arrangements available for various frame sizes are shown in table 1.Table 1

| Frame Size | Mounting Arrangements (IM) |

| 80 ~ 160 | B3, B5, B6, B7, B8, B35, V1, V3, V5, V6, V15, V36 |

| 180~225 | B3, B5B35, V1 |

| 250 ~ 355 | B3, B35, V1 |

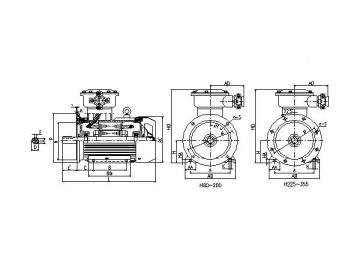

Technical Data and Mounting and Overall Dimensions

Mounting and overall dimensions are shown in tables 2-5

Note: Data is for reference only and may change based on customizations. Contact us with any questions.

| Type | Power kW | Current A | Type | Power kW | Current A | Type | Power kW | Current A | Type | Power kW | Current A | ||||

| 380V 50Hz | 440V 60Hz | 380V 50Hz | 440V 60Hz | 380V 50Hz | 440V 60Hz | 380V 50Hz | 440V 60Hz | ||||||||

| YB280M1-2-H | 0.75 | 1.8 | 1.6 | YB2355L-2-H | 315 | 566 | 502 | YB2315L2-4-H | 200 | 361.3 | 318.9 | YB2355M1-6-H | 160 | 302.0 | 265.3 |

| YB280M2-2-H | 1.1 | 2.6 | 2.2 | YB280M1-4-H | 0.55 | 1.5 | 1.4 | YB2355M-4-H | 250 | 464 | 410 | YB2355M2-6-H | 200 | 377 | 331 |

| YB290S-2-H | 1.5 | 3.5 | 3.1 | YB280M2-4-H | 0.75 | 2.1 | 1.8 | YB2355L-4-H | 315 | 582 | 514.0 | YB2355L-6-H | 250 | 469 | 412 |

| YB290L-2-H | 2.2 | 4.9 | 4.3 | YB290S-4-H | 1.1 | 2.7 | 2.4 | YB290S-6-H | 0.75 | 2.2 | 2.0 | YB2132S-8-H | 2.2 | 5.8 | 5.2 |

| YB2100L-2-H | 3 | 6.2 | 5.4 | YB290L-4-H | 1.5 | 3.6 | 3.2 | YB290L-6-H | 1.1 | 3.2 | 2.9 | YB2132M-8-H | 3 | 7.6 | 6.8 |

| YB2112M-2-H | 4 | 8.2 | 7.2 | YB2100L1-4-H | 2.2 | 5.0 | 4.5 | YB2100L-6-H | 1.5 | 4.0 | 3.5 | YB2160M1-8-H | 4 | 10.5 | 9.1 |

| YB2132S1-2-H | 5.5 | 11 | 9.6 | YB2100L2-4-H | 3 | 6.8 | 5.9 | YB2112M-6-H | 2.2 | 5.8 | 5.2 | YB2160M2-8-H | 5.5 | 13.4 | 11.5 |

| YB2132S2-2-H | 7.5 | 14.6 | 12.9 | YB2112M-4-H | 4 | 8.9 | 7.7 | YB2132S-6-H | 3 | 7.2 | 6.4 | YB2160L-8-H | 7.5 | 17.7 | 15.5 |

| YB2160M 1-2-H | 11 | 21.6 | 18.7 | YB2 132S-4-H | 5.5 | 11.7 | 10 | YB2132M1-6-H | 4 | 9.5 | 8.2 | YB2180L-8-H | 11 | 25.6 | 22.2 |

| YB2160M2-2-H | 15 | 28.9 | 25.1 | YB2132M-4-H | 7.5 | 15.4 | 13.2 | YB2132M2-6-H | 5.5 | 12.5 | 10.7 | YB2200L-8-H | 15 | 33.3 | 29.2 |

| YB2160L-2-H | 18.5 | 35.7 | 30.3 | YB2160M-4-H | 11 | 22.6 | 19.5 | YB2160M-6-H | 7.5 | 17.1 | 14.8 | YB2225S-8-H | 18.5 | 40.3 | 35.6 |

| YB2180M-2-H | 22 | 42.2 | 36.9 | YB2160L-4-H | 15 | 30.5 | 26.3 | YB2160L-6-H | 11 | 25.0 | 21.7 | YB2225M-8-H | 22 | 47.4 | 41.7 |

| YB2200L1-2-H | 30 | 57.9 | 50.3 | YB2180M-4-H | 18.5 | 35.9 | 30.8 | YB2180L-6-H | 15 | 33.0 | 29.3 | YB2250M-8-H | 30 | 64.7 | 57.1 |

| YB2200L2-2-H | 37 | 69.4 | 60.3 | YB2180L-4-H | 22 | 42.2 | 36.9 | YB2200L1-6-H | 18.5 | 37.6 | 32.7 | YB2280S-8-H | 37 | 79.8 | 68.9 |

| YB2225M-2-H | 45 | 85.9 | 76.3 | YB2200L-4-H | 30 | 57.3 | 49.8 | YB2200L2-6-H | 22 | 44.7 | 38.9 | YB2280M-8-H | 45 | 94.8 | 80.8 |

| YB2250M-2-H | 55 | 103.2 | 91.7 | YB2225S-4-H | 37 | 70.2 | 60.3 | YB2225M-6-H | 30 | 61.1 | 53.1 | YB2315S-8-H | 55 | 113.5 | 98.59 |

| YB2280S-2-H | 75 | 139.2 | 120.9 | YB2225M-4-H | 45 | 84.0 | 73.4 | YB2250M-6-H | 37 | 71.0 | 61.3 | YB2315M-8-H | 75 | 152.1 | 132.0 |

| YB280M-2-H | 90 | 167.1 | 143.5 | YB2250M-4-H | 55 | 103.8 | 88.7 | YB2280S-6-H | 45 | 86.4 | 74.6 | YB2315L1-8-H | 90 | 179.3 | 155.6 |

| YB2 315S-2-H | 110 | 203.0 | 180.2 | YB2280S-4-H | 75 | 139.2 | 120 | YB2280M-6-H | 55 | 103.2 | 89.7 | YB2315L2-8-H | 110 | 218.4 | 189.6 |

| YB2315M-2-H | 132 | 242.3 | 215.1 | YB2280S-4-H | 90 | 164.3 | 141.9 | YB2315S-6-H | 75 | 141.1 | 123.9 | YB2355M1-8-H | 132 | 265 | 230 |

| YB2315L 1-2-H | 160 | 292.1 | 259.3 | YB2 315S-4-H | 110 | 200.8 | 177.3 | YB2315M-6-H | 90 | 168.6 | 148.1 | YB2355M2-8-H | 160 | 320 | 278 |

| YB2315L 2-2-H | 200 | 365.1 | 324.1 | YB2315M-4-H | 132 | 239.7 | 211.6 | YB2315L1-6-H | 110 | 205.4 | 180.4 | YB2355L-8-H | 200 | 399 | 347 |

| YB2355M-2-H | 250 | 451 | 401 | YB2315L 1-4-H | 160 | 289.0 | 255.1 | YB2315L2-6-H | 132 | 245.7 | 215.8 | | |||

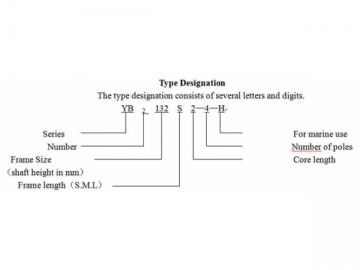

Ordering Information

1. When placing an order, specify the motor’s type, output, number of poles, voltage, frequency, mounting arrangement and any other requirements.

2. Customized features include the double shaft extension, position of the terminal box, and the thermistor protection.