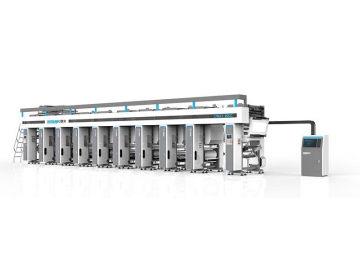

High Speed Rotogravure Press, DGAY1050D Wide Format Printing

Request a Quote

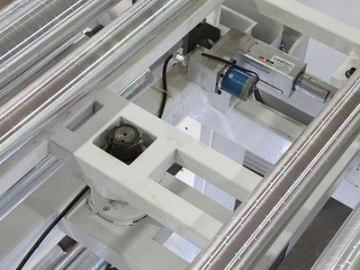

High speed rotogravure press DGAY1050DE is driven by electronic line shaft, which brings less mechanical wear and vibration. The multi-color register is controlled by servo motors, which ensures the printing precision and help the press adapt to higher speed.

This high speed rotogravure press can reach printing speed up to 220m/min. For clients who have requirement for frequent mass production, this high speed rotogravure press can be your perfect choice.

Adaptive material of print surfaceBOPP,CPP,PET,PC,PVC and composite film or paper, etc. of the same texture.

| Model | DGAY1050D(Electrical line shaft) |

| Printing width | 1050mm |

| Material width | 1080mm |

| Printing cylinder diameter | 100-350mm |

| Printing speed | 220m/min |

| Unwind diameter | 600mm |

| Rewind diameter | 600mm |

| Register accuracy | Vertical and horizontal both±0.1mm |

| Total power | 380KW |

| Weight | 40000KG |

| Dimension | 16000×4450×3145mm |

1. Shaftless drive system is equipped in this press, providing less wear and higher efficiency. Each printing unit is separately controlled by servo motors, enabling the machine to print at a higher speed.

1. Shaftless drive system is equipped in this press, providing less wear and higher efficiency. Each printing unit is separately controlled by servo motors, enabling the machine to print at a higher speed.  2. The video surveillance system controlled by computer is installed, ensuring the printing precision and the quality of multi-color printing.

2. The video surveillance system controlled by computer is installed, ensuring the printing precision and the quality of multi-color printing.  3. Combined drying system built out is more efficient than ones built-in. Forced air heating system can be installed. Energy expenditure of the drying system can be reduced at most 80%.

3. Combined drying system built out is more efficient than ones built-in. Forced air heating system can be installed. Energy expenditure of the drying system can be reduced at most 80%.  4. Chilling roller cools and help maintaining the structure of the flattened flexible web materials, providing convenience for following printing process.

4. Chilling roller cools and help maintaining the structure of the flattened flexible web materials, providing convenience for following printing process.  5. Dual-position unwinding system is equipped with electrostatic eliminator.

5. Dual-position unwinding system is equipped with electrostatic eliminator.  6. EPC device can be installed on the unwinding system.

6. EPC device can be installed on the unwinding system.  7. Reverse roller can be installed on this high speed rotogravure press to ensure consistence of the two sides of the printing.

7. Reverse roller can be installed on this high speed rotogravure press to ensure consistence of the two sides of the printing.

Related products

Send Message

Most Recent

More

Other Products

Videos