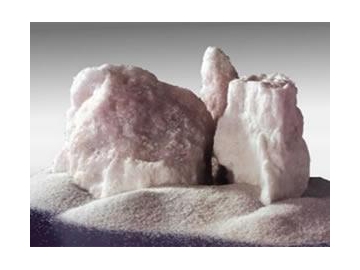

102A Claus Catalyst Activated Alumina in Sulfur Recovery Process

Request a Quote

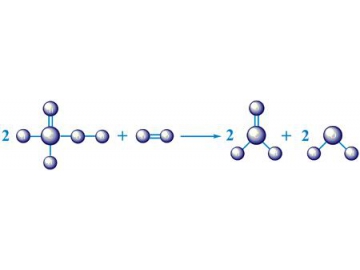

102A claus catalyst activated alumina applied in the sulfur recovery process is mainly used to catalyze the claus sulfur recovery technique in which hydrogen sulfide reacts with sulfur dioxide to generate pure sulfur.

Chemical composition (wt%)

- AL2O3 (wt%): 93.5

- Na2O (wt%): 0.25

- Fe2O3 (wt%): 0.02

- SiO2 (wt%): 0.02

| Appearance | White spherical |

| Specification | Φ4-6 ( 3/16' ) |

| Ignition loss( 300-1000 ℃ ) (wt%) | 4-7 |

| Specific surface area( m2/g ) | 330 |

| Total pore volume (cc/g ) | 0.45-0.50 |

| Bulk density (g/cm3 ) | 0.70-0.80 |

| Compressive strength( N/sphere ) | 200 |

| Macroporosity > 750 Å | 0.14 |

| Abrasion loss ( wt% ) | 0.1 |

| LOI (wt%) | 6.5 |

Package

25kg/bags, 500kg/bags, 800kg/bags, 1000kg/bags, 150kg/drum, 2000LB/bags.

Related products

Send Message

Most Recent

More

Other Products

Videos