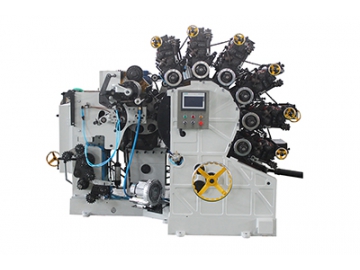

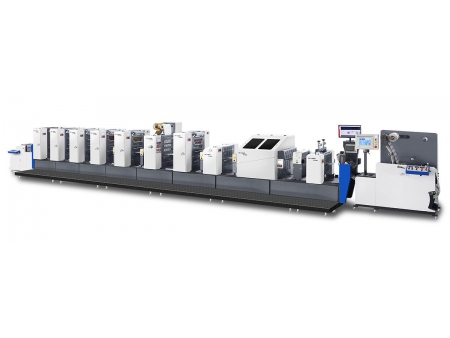

Offset printing machine

Description of product

The YSG01 aluminum tube printing machine is suitable for printing patterns on the surface of metal tube such as aluminum tube and aluminum can. The YSG01 aluminum tube printing machine can be printed with up to six different color patterns.

The billet tube from the base color printing oven is driven to the upper tube of the press by the conveyor chain. The billet tube enters the falling tube groove and the blank tube is inserted into the printing mandrel by the pushing rod. The ink passes through the ink slot, the ink roller, the middle roller, the string roller and the rubber roller to the printing plate. The image and text to be printed is transferred from the printing plate to the blanket roller and printed on the aluminum tube with appropriate pressure. The printed tube is removed from the central mandrel by a manipulator and plugs in the oven link and enter the oven for drying with the oven chain. Aluminum tube printing adopts rotary mode for polychrome printing.

Technical parameter- Suitable diameter: 16-25mm25-35mm

- Maximum suitable length of tube: 250mm

- Production rate: 100-120 tubes/minute

- Main motor: 19.17KW

- Inlet pressure: 0.6MPa

- Dimension: 3445*2318*2168mm

- Total weight: About 9.6 tons

- The whole machine is controlled by Siemens PLC, and the pro-face color touch screen displays the production rate and current output, etc. The automatic detection device can dont print when there is no tube and stop automatically when the tube is not good. The printing central spindle rotates and can be adjusted by frequency conversion. The printing part adopts the structure of support plate R plate, which is convenient to change specifications.

- The clicking adjustment handle makes printing adjustment more convenient.

- The drawer type printing components, which is easy and fast to replace the printing plate.

- In order to adapt to the printing of aluminum tubes of different specifications, the central mandrel parts are replaced as a whole. It is convenient and fast to replace the central mandrel with quick change mandrel.