ER 1100 (AL99.0Cu) Aluminium Welding Wire

Request a Quote

Welding Consumables

99% aluminium filler metal for MIG and TIG welding of mostly pure aluminium basis alloys

- Chemical Designation: AL99.0Cu

- Standard: AWS A5.10, GB/T10858-2023

- Tensile Strength: ≥75 MPa

Chemical Composition (%)

| Si Fe | Cu | Mn | Zn | AL | Be | Others | |

| Each | Total | ||||||

| ≤0.95 | 0.05-0.20 | ≤0.05 | ≤0.10 | ≧99.00 | ≤0.0003 | ≤0.05 | ≤0.15 |

Features

- Made with 99% aluminium, ensuring stable electrical conductivity

- Offers dependable corrosion resistance along with flexibility and strength

- Delivers smooth color matching after anodizing, ideal for clean, visible weld finishes

Available Sizes

- Welding wire: 0.8/1.0/1.2/1.6/2.0/2.4/3.0/3.2/4.0/5.0/6.0mm

- Spool: D300 (9kg), D270 (7kg), D200 (2kg), D100 (0.5kg)

Applications

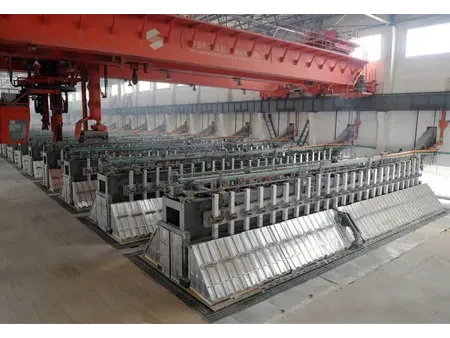

This aluminium welding wire is commonly used for welding pure aluminium components, including:

- Aluminium sheets (grades 1100, 1050, 1350, 1450, 1060, 1070, 1080)

- Busbars, conductors, and aluminium channels

- Components for nuclear equipment

- Aluminium boats, fishing containers, and tanks

- Signboards, display frames, and decorative pieces

- Aluminium profiles, cold storage truck panels, and more

Packaging

- MIG wire diameter: 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm

- Package: D300 (9kg/spool), D270 (7kg/spool)

- MIG wire diameter: 1.2mm, 1.6mm

- Package: drum D660 (100kg/drum, 80kg/drum)

- TIG wire diameter: 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Package: 1000mm length (10kg/box)

- TIG wire diameter: 1.6mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Coil inner diameter: D450mm, D300mm

- Package: 10-17kg/coil

Recommended Welding Method

ER1100 aluminium welding wire is suitable for both MIG and TIG welding. AC TIG welding with pure argon shielding gas is recommended for optimal results. Before starting, ensure the part to be welded is clean and free of oil or dust. Avoid any moisture on the workpiece, the welding wire, or in the environment, as it can affect weld quality.