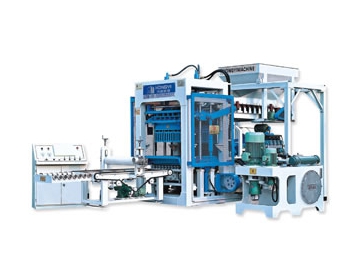

Zenith 940 Mobile Multilayer Block Machine

Application

The Zenith 940 mobile multilayer block machine can mass-produce almost all kinds of hollow brick, paver brick, curbstone and other cement products on the market. This block making machine can also produce a variety of non-standard and special products that cannot be produced by single pallet equipment.

Overview

The Zenith 940 multilayer block machine is multifunctional mobile equipment, and can manufacture high quality concrete cable duct, servicing silo, prefab, even the fence brick with a height of 1m and other special products in large scale. Each layer of the product is protected and separated with dry sand or plastic foil.

Multilayer production has outstanding advantages. Wet brick stack can be cured directly and packed, eliminating many intermediate transport processes.

German Zenith products are famous for quality and safety, providing low maintenance costs and improvign production efficiency. The optimized quality control and simple control system ensure the equipment of high level production performance.

Technical parameters| Features | |

| Base material hopper | 1200 L |

| Base material feedbox | 2000 L |

| Pigments hopper | 800 L |

| Pigments feedbox | 2000 L |

| Max.feeding height of loader | 2800 mm |

| Forming size | |

| Max.forming length | 1240 mm |

| Max.forming width (producing on the vibration table) | 1000 mm |

| Max.forming width (producing on the ground) | 1240 mm |

| Product height | |

| 1. multilayer production | |

| Min.product height (producing on the pallet) | 50 mm |

| Max.product height | 250 mm |

| Max.stacking height (pallet+ height of one layer product) | 640 mm |

| 2. low level production on the pallet | |

| Max.product height | 600 mm |

| 3. Low level production on the floor | |

| Max.product height | 650 mm |

| 4. production on the floor | |

| Max.product height | 1000 mm |

| Min.product height | 250 mm |

| Machine weight | |

| Without mould and pigments device | 11.7 T |

| Pigments device | 2.7 T |

| Machine size | |

| Total length (without pigments device) | 4400 mm |

| Total length (with pigments device) | 6380 mm |

| Max.total height | 3700 mm |

| Min.total height (transport height) | 3240 mm |

| Total width (including control panel) | 2540 mm |

| Vibration system | |

| Max. Exciting force of the vibration table | 80 KN |

| Max. Exciting force of the upper vibration | 40 KN |

| Energy consumption | |

| Based on the maximum number of vibrating motor | 42 KW |

Technical advantages

Intelligent operating:

This block machine uses advanced intelligent interactive system, together with Siemens touch screen and data input and output device. This system has functions of product formula management and collecting operating data, also having many optional languages. The visualized operating interface is friendly and the control system includes security logic control and fault diagnosis systems.

Hydraulic driving system:

The hydraulic power consists of two sets of piston pump. And the speed and pressure of the hydraulic action can be precisely controlled simultaneously or independently via proportional valve. All parameters can be set on the touch screen. The main movements of the machine, like the moving of vibration table, the lifting of mould frame and tamper head and the moving of feedbox, etc., are driven by the hydraulic system self-developed by Zenith.

Mobile production:

The concrete block making machine is equipped with guide wheels to realize mobile production. Driven by hydraulic motor, the operating is stable and reliable. The front wheel with hydraulic brake system positions precisely. The mobile production can be controlled and set via touch screen.

Coaxial and synchronous movement:

The mould frame and the tamper head move synchronously along the large guiding rod and guiding shaft through the chain and lever shaft. This ensures that the mould frame and tamper head can move safely, stably and precisely. Moreover, linear coder can be added to further enhance the moving.

Multifunctional feeding system:

The system is composed of hopper, guide rail, feedbox and lifting device. The unique mould scraper driven by hydraulic pressure ensures clean product surface. A fast feeding fence driven by hydraulic pressure inside the feedbox guarantees uniform feeding. The adjustable mould brush fixed on the feedbox is used to clean the upper parts of the mould.

Equipment configuration

The concrete products can be manufactured in multilayer

The concrete products can be manufactured in multilayer Movable vibration table

Movable vibration table Speed & Comfort

Speed & Comfort Production control

Production control

1. Cement silo

2. Four-silo aggregate batching plant

3. Dual-silo pigments batching plant

4. Aggregate mixer

5. Pigments mixer

6. Full automatic block making machine

7. Forklift truck

8. Loader

9. Ferry car

10. Material yard

11. Finished products area

12. Four-way block clamp

Product sample drawing

Block of insulation wall

Block of insulation wall  Curb brick

Curb brick  Colored pavement brick

Colored pavement brick

Residential retaining wall

Residential retaining wall Park fence and pavement

Park fence and pavement Square fence

Square fence

South Afria

South Afria- Tanzia

- Tanzia

- Ukraine

- Ukraine

- Chile