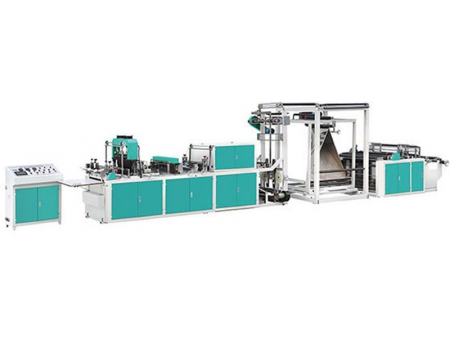

Fully Automatic Non-woven Box Type Bag with Handle Making Machine, WFB-BT600

Plastic Bag Machine/ Bag Manufacturing Equipment/ Bag Maker

Introduction

This machine can make five kinds of bags and it is fully automatic. This equipment is commonly used in in the production of various types of non-woven handle bag, flat bag, box bag, T-shirt bag, organ bag, gift bag, pillow bag, drawstring bag, etc. The different bags can be produced by simply changing the input material. The automatic positioning and bonding handle offers extra high quality production capabilities.

Applied Materials

This machine is suitable for BOPP woven fabric, regeneration non-woven and lamination non-woven fabric material.

The material thickness range: 20-120gsm.

Products Application

That product mainly used for food packaging, clothing packaging, shoe packaging, etc.

-

D-cut bag

D-cut bag -

Flat bag

Flat bag -

Draw string bag

Draw string bag -

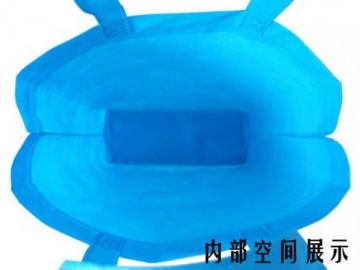

Box bag

Box bag -

Handle bag

Handle bag -

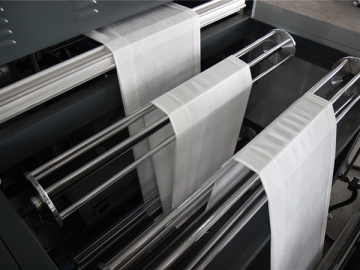

Internal structure

Internal structure

Advantages

1. It is a multi-function non woven bag making machine and can make five kinds of bags, such as flat bags, box bags, handle bags, shoe bags and D-cut bags.

2. It is a fully automatic non woven bag making machine. From the material to final bags, all processes are controlled by computer, including size, mouth of bag, etc.

3. It is an all in one non woven bag making machine. It can make the bag and handle loop at the same time.

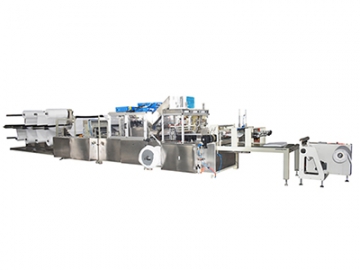

Machine Produce Process

Raw material steel -- cut and weld -- paint -- assemble configuration -- connect wiring -- finish -- test

-

Bottom

Bottom -

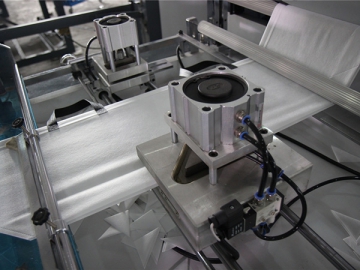

Computer control

Computer control -

Conveyor

Conveyor

-

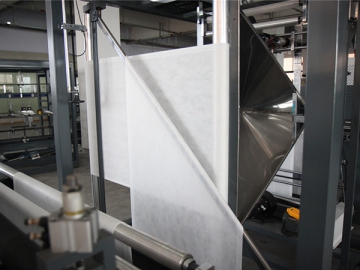

Fold it half

Fold it half -

Handle machine

Handle machine -

whole

whole

| Shape | Ours | Others' |

| Flat bag | 70 | 60 |

| Box bag | 55 | 50 |

| Shoe bag | 90 | 80 |

| Handle bag | 60 | 50 |

Bag Produce Process

1. The machine can make five kinds of bags. You only need to change the settings and the input material if necessary.

2. Printing on the material is to be performed prior to bag production.

For example:

(1) Box bag producing process:

Raw material roll(printing is outside) -- fold mouth of bag -- fold in half -- fold the bottom and seal -- make handle -- square punching bottom of bag -- ultrasonic seal side -- cut -- finish

(2) Flat bag producing process:

Raw material roll(printing is inside) -- fold mouth of bag -- fold in half -- make handle -- ultrasonic seal side -- cut -- finish

(3) We also provide a sllitting and rewinding machine for the handle.

| Model | WFB-BT600 |

| Max. Bag Making Width | 600mm |

| Bag Making Thickness Range | 20-100g |

| Max. Bag Making Length | 700mm |

| Production Speed | 40-90pcs/min |

| Total Power | 14kw |

| Machine Weight | 3.2t |

| Overall Dimensions | 11500*2000*2100mm |

Attention

1. Voltage

Two phase 220V

Three phase 380V

2. Temperature

You must preheat the machine before starting the operation

3. Ultrasonic computer controller

Ult Power meter no more than 0%

Horn Match Meter no more than 5%

FAQ:

Q: How many people operate the machine?

A: One or two persons.

Q: Do I need any additional equipment?

A: You can buy a slitting and rewinding machine for the handle in order to increase efficiency.

Q: How long is the warranty period?

A: The guaranty period is one year after the installation and adjustment.

Q: Do you supply installation and training in my country?

A: Yes, we will arrange travel for our engineers to the buyer’s factory for machine installation and training. The buyer should pay the round-trip ticket cost, hotel, and food for our team. Usually this can be completed within a week. The buyer is also responsible for paying 80 USD/day salary to our engineer.

Q: If there is some problem with machine running, how long will it take to resolve?

A: We will reply to you within 24 hours and solve it within 48 hours.