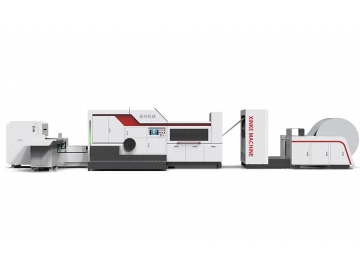

SOS Paper Bag Making Machine XKFD-220/280/330/450/540

Roll-fed Paper Bag Making Machine for Self Opening Sack (SOS) Bag

This paper bag making machine is a block bottom bag machine that uses blank or printed paper roll as raw material to produce various types of paper bag with square bottom. By adopting Mitsubishi servo motor control system, this paper bag machine can conduct an automatic production process through each step of paper roll unwinding, side gluing, print mark detecting (photoelectric sensor), folding & tube forming, cutting, bottom opening, bottom gluing, bottom forming and final bag collecting.

Our paper bag making machine can be equipped with in-line printer and die cut handle device which enable paper shopping bags or paper carrier bags to be crafted in a wide assortment of styles adapted to user preferences, while adding marketing value to every item.

- Unwinding

- Side gluing

- Tube forming

- Cut off

- Creasing

- Bottom opening

- Bottom gluing

- Bottom folding

- Final bag

- Model: XKFD-220

- Speed: 30-200pcs/min

- Cutting length: 190-370mm

- Paper bag length : 150-320mm

- Paper bag width : 80-220mm

- Paper bag bottom width : 55-100mm

- Side overlap width: 20-30mm

- Bottom overlap width: 10-20mm

- Paper roll width: 290-670mm

- Paper roll diameter: 1300mm

- Paper thickness: 50-130gsm

- Paper core diameter: 76mm(3")

- Machine power: 10kW

- Air source: 0.06MPa

- Machine weight : 5500kg

- Machine size: 8000x2980x1800mm

- Model: XKFD-280

- Speed:30-180pcs/min

- Cutting length:270-530mm

- Paper bag length :225-470mm

- Paper bag width :120-280mm

- Paper bag bottom width :60-180mm

- Side overlap width:25-30mm

- Bottom overlap width:15-25mm

- Paper roll width:385-950mm

- Paper roll diameter:1300mm

- Paper thickness:60-160gsm

- Paper core diameter:76mm(3")

- Machine power:12kW

- Air source:0.06MPa

- Machine weight :7000kg

- Machine size:9700x2980x1900mm

- Model: XKFD-330

- Speed: 30-160pcs/min

- Cutting length: 270-530mm

- Paper bag length : 225-470mm

- Paper bag width : 150-330mm

- Paper bag bottom width : 60-160mm

- Side overlap width: 25-30mm

- Bottom overlap width: 15-25mm

- Paper roll width: 445-1050mm

- Paper roll diameter: 1300mm

- Paper thickness: 60-160gsm

- Paper core diameter: 76mm(3")

- Machine power: 12kW

- Air source: 0.06MPa

- Machine weight : 8000kg

- Machine size: 9800x2980x1900mm

- Model: XKFD-450

- Speed: 30-150pcs/min

- Cutting length: 285-530

- Paper bag length : 225-470mm

- Paper bag width : 220-460mm

- Paper bag bottom width : 80-220mm

- Side overlap width: 30mm

- Bottom overlap width: 20-30mm

- Paper roll width: 630-1390mm

- Paper roll diameter: 1300mm

- Paper thickness: 80-160gsm

- Paper core diameter: 76mm(3")

- Machine power: 15kW

- Air source: 0.06MPa

- Machine weight : 10000kg

- Machine size: 10200x3150x2200mm

- Model: XKFD-540

- Speed: 30-120pcs/min

- Cutting length: 420-760mm

- Paper bag length : 320-680mm

- Paper bag width : 250-540mm

- Paper bag bottom width : 120-260mm

- Side overlap width: 30-40mm

- Bottom overlap width: 20-30mm

- Paper roll width: 770-1640mm

- Paper roll diameter:

- Paper thickness: 90-160gsm

- Paper core diameter:

- Machine power: 18kw

- Air source: 0.06MPa

- Machine weight : 13000kg

- Machine size: 11250x3400x2160mm

| Model | XKFD-220 | XKFD-280 | XKFD-330 | XKFD-450 | XKFD-540 |

| Speed | 30-200pcs/min | 30-180pcs/min | 30-160pcs/min | 30-150pcs/min | 30-120pcs/min |

| Cutting length | 190-370mm | 270-530mm | 270-530mm | 285-530 | 420-760mm |

| Paper bag length | 150-320mm | 225-470mm | 225-470mm | 225-470mm | 320-680mm |

| Paper bag width | 80-220mm | 120-280mm | 150-330mm | 220-460mm | 250-540mm |

| Paper bag bottom width | 55-100mm | 60-180mm | 60-160mm | 80-220mm | 120-260mm |

| Side overlap width | 20-30mm | 25-30mm | 25-30mm | 30mm | 30-40mm |

| Bottom overlap width | 10-20mm | 15-25mm | 15-25mm | 20-30mm | 20-30mm |

| Paper roll width | 290-670mm | 385-950mm | 445-1050mm | 630-1390mm | 770-1640mm |

| Paper roll diameter | 1300mm | ||||

| Paper thickness | 50-130gsm | 60-160gsm | 60-160gsm | 80-160gsm | 90-160gsm |

| Paper core diameter | 76mm(3") | ||||

| Machine power | 10kW | 12kW | 12kW | 15kW | 18kw |

| Air source | 0.06MPa | ||||

| Machine weight | 5500kg | 7000kg | 8000kg | 10000kg | 13000kg |

| Machine size | 8000x2980x1800mm | 9700x2980x1900mm | 9800x2980x1900mm | 10200x3150x2200mm | 11250x3400x2160mm |

- Hydraulic Loading

Paper roll is loaded using hydraulic system, easy to operate. - Touch Screen

HMI touch screen monitor with PC control system will show the machine working status in real time, and servo motor drives the paper bag machine to guarantee the operation stability. - Paper Bag Forming Unit

This unit can form the paper bags in one process, efficiently improving bag production efficiency while reducing manufacturing wastes and time. - Print Mark Detecting System

SICK photoelectric sensor detects print marks accurately, enabling the cutting position of paper bag to be precisely located. - Collecting Table

This table is placed transversely, greatly facilitating packaging and significantly reducing labor intensity. - Designed with a special adjustment mechanism, reduced adjustment time and high adjustment precision are ensured, which significantly increases the production efficiency, and reduces the waste.

- The automatic web guiding system is used in the unwinding section, which constantly corrects the position of the web. Due to the double photoelectric switch, the motor equipped for the web guiding system doesn’t need to work frequently, significantly reducing energy consumption and improving service life.

- The paper bag making machine is driven by two large capacity servo motors and one general servo motor, ensuring edge folding and bottom opening are performed in a precise manner. As a result, highly accurate bag size will be achieved.

- The paper bag production machine comes with an independent glue mixing unit, which can continue with mixing operation after machine stops working. This prevents it from drying out. In addition, automatic glue supplying is achieved.

For more than 20 years we have been a paper packaging machine manufacturer specializing in the paper bag market. We are committed to helping our customers design and manufacture paper bag machines with results beyond their expectations. Whether you need to produce small paper grocery bags, large paper shopping bags, with twisted handle or flat handle, our paper bagging machinery can get the job done efficiently.