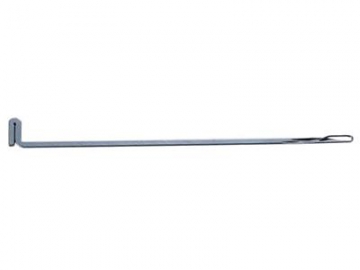

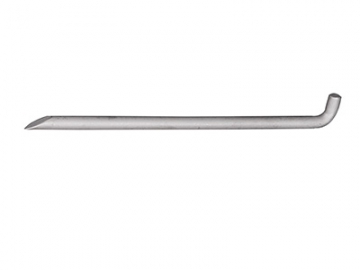

Spring Bearded Needle on Tricot Machines

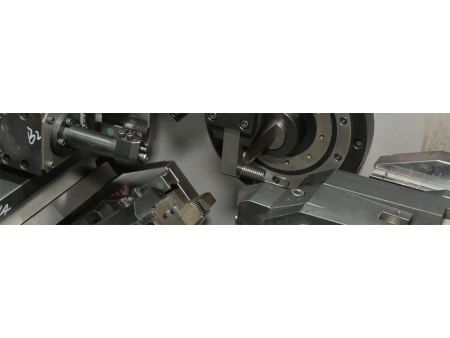

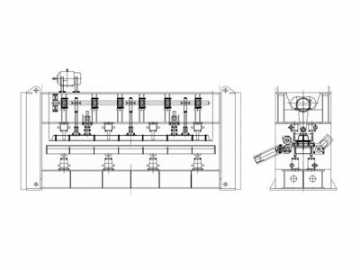

Spring bearded needles have been more frequently been replaced by compound and latch needles as technology improves, but they are still widely used in traditional tricot warp knitting machines.

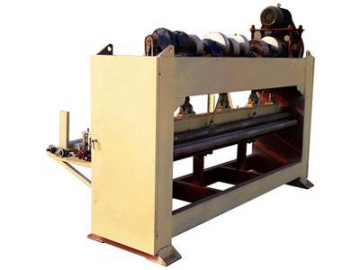

The spring bearded needle does require a pressing tool in order to close the bearded hook, as the beard and head come into direct contact with the yarn, which requires an exceptionally large tension while operating. Wear resistance and surface smoothness are the biggest concerns during production, which is why we use high quality steel strips and wires from Japan and Germany to manufacture beard needles and improve the hardness. Spring bearded needles are made with high precision stamping dies, and treated with polishing, chamfering, and deburring processes to enhance accuracy and smoothness. YS bearded needles are quality guaranteed due to excellent raw material and precise manufacturing.

YS has successfully manufactured a great variety of bearded needles for many brands of tricot warp knitting machine. You are only asked to provide your model or current using needles, we can ship you YS samples for free trials in fastest possible speed or manufacturing specific beard needles just for you.

YS has rich experience in mass production of compound needles for common warp knitting machine brands like Karl-Mayer, LIBA and crocheting machines like Muller, TCH, DAHU, KY, COMEZ and etc. You are only asked to provide your model or current using needles, we can ship you YS samples for free trials as fast as possible or customizing samples just for you.