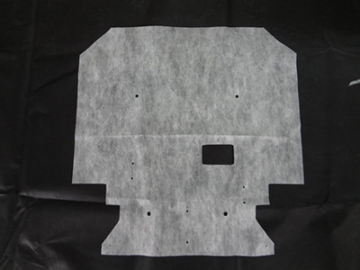

Custom Seat Component Pad

The complete automotive seat consists of the seat frame, seat foam and seat cover. In order to reduce noise caused by friction between seat foam and seat frame, wax is often used by seat manufacturers. Here, Dongping Plastic demonstrates a better solution in a seat component pad. Application is simple, and the noise reduction effect is much better.

The seat component pad is placed on the framework of the car seat, and is designed to prevent and reduce noises caused by friction between the foam material and framework.

non-woven fabrics, cut cloth, MDPE

Thickness 0.02 ~0.08mm. Weight, shape and size specification can be customized.

Blowing film → blanking → sealing

- Dongfeng Nissan: Infiniti, Teana, X-Trailx-Trail, Sunny, Venucia

- Honda: CRV

- Toyota: RAV4, Highlander, Reiz, Crown, Prius, Prado, Previa, Land Cruiser

- Luxgen: L7 ,5, R3, U6, U5

- Geely: Imperial

- Japanese Daihatsu: Pico, materia, Copen,Sirion, Xenia

- Hawtai: SantaFe, Road, Bolgheri

Note: We have ready-made molds of the above types, allowing them to be manufactured and processed quickly. If you do not see the type you need, simply contact us for customization.

We have passed ISO/TS16949 auto quality certification systems standards. Our seat component pad is nontoxic, odorless, durable and features an excellent toughness and wear resistance, giving them a service life up to 20 years. We will test the appearance and density of each batch before leaving factory. If their inspection is deemed qualified, we will certify the components.

| Item | Technical standard | Testing methods | Testing standard |

| Appearance | It is uniform and white nonwoven fabric | visual inspection | ―― |

| Combustibility | 100mm/min | 356mm×100mm,(21±2)℃, (50±5)%RH,24h | NES M0094 |

| Shelf Life | 12 months | 5~35℃,Put it in a cool, dry room | ―― |