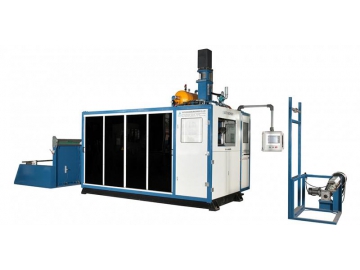

TCC Plastic Container Thermoforming Machine

Description

TCC plastic container thermoforming machine is a kind of multifunction equipment composed of thermoforming machine, automatic punching machine, cutting machine and stacking machine, which can automatically perform punching, cutting, counting, stacking and so on after thermoforming.

The plastic products manufactured by our machine has smooth incision, which is very suitable for food packaging.

Therefore, TCC plastic container manufacturing line is widely applied to continuous manufacture of all kind of disposable plastic fruit containers with holes, trays, bowl cover, and other plastic products with holes.

Technical progress

(1)ATY40 Forming unit

| Suitable Material | PP、PS、PET、PVC、PLA | \ |

| Main motor power | 11 | kW |

| Stretching servo motor power | 7.5 | kW |

| Sheet thickness | 0.3-2.0 | mm |

| Max.Forming depth | 140 | mm |

| Max.Work efficiency | 30 | pcs/min |

| Maximum forming area | 680×265 | mm |

| Air consumption | 3200-4000 | L/min |

| Heating power | 101 | kW |

| Total weight | 6 | T |

| Suitable Material | PP、PS、PET、PVC、PLA | \ |

| Main motor power | 15 | kW |

| Stretching servo motor power | 11 | kW |

| Sheet thickness | 0.3-2.0 | mm |

| Max.Forming depth | 170 | mm |

| Max.Work efficiency | 36 | pcs/min |

| Maximum forming area | 680×390 | mm |

| Air consumption | 4000-5000 | L/min |

| Heating power | 101 | kW |

| Total weight | 8 | T |

Feature

1. TCC plastic container thermoforming machine can achieve one-stop high speed manufacture. Besides, the forming unit and punching unit can operation independently.

2. The manufacturing line is driven by servo motor and can be controlled automatically by PLC program. Besides, the machine has high punching and positioning precision.

3. The part of thermoforming machine can be equipped with cam transmission or hydraulic transmission based on the customers’ requirement.

(1)CQ40-750 Punching Unit

| Max.punching area | 680×240 | mm |

| Max.punching speed | 80 | time/min |

| Max.die set height | 290-350 (adjustable) | mm |

| Punching stroke | 160 | mm |

| Main motor power | 11 | kW |

| Max.punching depth | 86 | mm |

| Max.punching force | 8 | KN |

| Total power | 14 | kW |

| Total weight | 5 | T |

| Max.punching area | 680×350 | mm |

| Max.punching speed | 80 | time/min |

| Max.die set height | 290-350 adjustable) | mm |

| Punching stroke | 160 | mm |

| Main motor power | 15 | kW |

| Max.punching depth | 86 | mm |

| Max.punching force | 15 | KN |

| Total power | 18 | kW |

| Total weight | 6.5 | T |