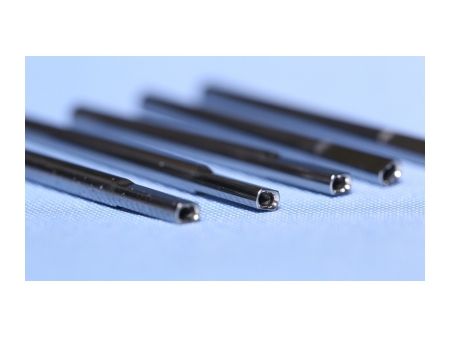

Zirconated Tungsten Electrodes

Our zirconated tungsten electrodes are specially developed to increase current-carrying capacity while improving arc starting and stability as well as increasing electrode life. Hence, the shortcomings that pure tungsten electrodes will melt in high load welding and then contaminate workpiece can be overcome.

The most prominent characteristic of the zirconium tungsten electrode is that it retains balled tip and resists tungsten spitting when carrying high current and has excellent resistance to contamination.

Similar with the pure tungsten electrode, the zirconated tungsten electrodes can only be used in AC welding. In AC welding, this tungsten welding rod provides great performance. Especially in high load current, its superior property is irreplaceable.

Technical Parameters

| Model | Oxide Additives | Oxide Content % | Impurities Content % | Tungsten | Color standard |

| ZrO2 | 0.20-0.40 | <0.20 | Balance | Brown | |

| ZrO2 | 0.70-0.90 | <0.20 | Balance | White |

Product Standards

ISO 6848, ANSI/AWS, A5.12/A5.12M-98

Specifications

1. Diameter: 0.5-25mm

2. Length: 150mm, 175mm, 178mm (other lengths depend on customer's requirements)

Electrode Diameter in Different Current Range

| Electrode Diameter | DC(A) | AC(A) | |||

| In | Mm | DCEN (-) | DCEP ( ) | Imbalanced Wave | Balanced Wave |

| 0.04" | 1.0 | 15-80 | 10-80 | 20-60 | |

| 1/16" | 1.6 | 60-150 | 10-18 | 50-120 | 40-100 |

| 0.079" | 2.0 | 100-200 | 12-20 | 70-160 | 60-130 |

| 3/32" | 2.4 | 150-250 | 15-25 | 80-200 | 80-150 |

| 1/8" | 3.2 | 220-350 | 20-35 | 150-270 | 120-200 |

| 5/32" | 4.0 | 350-500 | 35-50 | 220-350 | 170-260 |

| 3/16" | 4.8 | 420-650 | 45-65 | 240-420 | 220-340 |

| 1/4" | 6.4 | 600-900 | 65-100 | 360-560 | 250-450 |