Heat Shrink Wire Marker, Printable Heat Shrink Tubing

Model: CYG-MT

Material: Radiation-crosslinked modified polyolefin

Shrink ratio: 3:1

Application

3:1 printable heat shrink tubing, with a product ID of CYG-MT, is designed to meet the high performance identification requirements for cables and equipment in a variety of manufacturing applications. Because the main material is a radiated cross linked modified polyolefin, it features an excellent abrasion and flame resistance, making it applicable for operation temperature ranges of - 55 ℃ to 135 ℃ for line identification in electrical equipment. The print performance of the material not only meets with SAE-AS-81531.4.6.2 and MIL-STD-202F standards, but is also inflammable and features an outstanding insulation performance. CYG’s 3:1 heat shrink tubing can be double printed and maintains its excellent print performance, even after long term rubbing, or exposure to harsh solvents and oils.

| Size (Inch) | As supplied | After recovery | |

| Inside diameter (mm) | Inside diameter (mm) | Wall thickness (mm) | |

| 3/32 | 2.4 | 0.8 | 0.53±0.08 |

| 1/8 | 3.2 | 1.07 | 0.58±0.08 |

| 3/16 | 4.8 | 1.6 | 0.58±0.08 |

| 1/4 | 6.4 | 2.11 | 0.61±0.08 |

| 3/8 | 9.5 | 3.2 | 0.61±0.08 |

| 1/2 | 12.7 | 4.2 | 0.61±0.08 |

| 3/4 | 19.1 | 6.35 | 0.64±0.08 |

| 1 | 25.4 | 8.46 | 0.64±0.08 |

| 1-1/2 | 38.1 | 12.7 | 1.0±0.08 |

| 2 | 50.8 | 16.9 | 1.0±0.08 |

| Item | Test methods | Specifications |

| Tensile Strength | SAE-AMS-DTL-23053 | ≥10.3MPa |

| Ultimate Elongation Ratio | SAE-AMS-DTL-23053 | ≥200% |

| Flexibility | SAE-AMS-DTL-23053.4.6.7 | -55℃±1℃, 4h, No cracking |

| Heat Shock | SAE-AMS-DTL-23053.4.6.8 | 250℃±3℃, 4h, No cracking, no dripping, no flowing |

| Aging Performance | SAE-AMS-DTL-23053.4.6.9 | 175℃±2℃, 168h, No visual damage |

| Tensile Strength After Aging | SAE-AMS-DTL-23053.4.6.13 and ASTM D638 | ≥6.9MPa, 23℃±2℃ |

| Ultimate Elongation Ratio After Aging | SAE-AMS-DTL-23053.4.6.13 and ASTM D638 | ≥100%, 23℃±2℃ |

| Color Stability | SAE-AMS-DTL-23053.4.6.15 | 175℃±2℃, 24h, Pass |

| Dielectric Strength | SAE-AMS-DTL-23053.4.6.13 and ASTM D2671 | ≥19.7kV/mm, 23℃±2℃ |

| Volume Resistance | SAE-AMS-DTL-23053.4.6.13 and ASTM D876 | ≥1.0x1014Ω· cm,500V(DC), 60s |

| Flammability | UL224 | Flame resistance |

| Fluid Resistance | AE-AMS-DTL-23053.4.6.11 | No visual damage |

| Print Persistence | SAE-AS-81531.4.6.2 | 50 rubber erasure, identification |

| Print Solvent Resistance | MIL-STD-202G Method 215K | 10 rubber erasure, identification |

| Item | Test methods | Specifications |

| Physical performance | ||

| Operation temp. | -55℃~135℃ | |

| Tensile strength (M Pa) | ASTM D2671 | ≥10.3Mpa |

| Ultimate elongation ratio (%) | ASTM D2671 | ≥200% |

| Flexibility (-55℃, 4hrs) | ASTM D2671 | No cracking |

| Heat shock at 250℃±3℃ at 4hrs | ASTM D2671 | No cracking, no dripping, no flowing |

| Electrical performance | ||

| Dielectric strength | ASTM D2671 | ≥19.7kV/mm |

| Volume Resistance | ASTM D876 | ≥1014Ω·cm |

| Flammability | UL224 | Flame resistance |

| Fluid resistance (23℃, 24hrs) | ASTM D2671 | Print identified |

| After Aging at 175℃±2℃ at 168hrs | ||

| Tensile strength (MPa) | ASTM D2671 | ≥6.9Mpa |

| Ultimate elongation ratio (%) | ASTM D2671 | ≥100% |

| MIL-M-81531-4.6.2 | 20 rubber erasure, identification | |

| Print performance | ||

| UL 224, | 50 Rubber erasure , identification | |

| MIL-M-81531-4.6.2 | 50 Rubber erasure , identification | |

| MIL-STD-202 | 30 Rubber erasure, identification | |

- The print material meets UL224 and halogen-free environmental standards.

- Print performance meet AS23053/5 requirements.

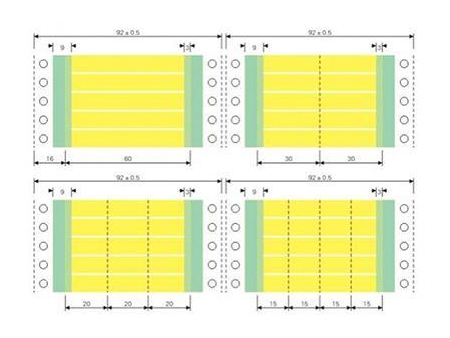

- Various product packaging methods to meet different customer requirements.

- Can be printed with a standard dot matrix printer or heat transfer printer.

- Readable with double-side printing

- Product color can be customized, with standard colors of white and yellow

- Great anti-pollution ability and print persistence.