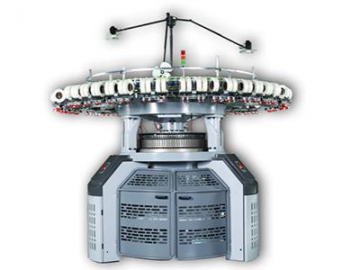

HCRD6J2 Double Jacquard Machine Knitting, Knitting Machine

Application:

HCRD6J2 Jacquard warp knitting machine is a Raschel warp knitting machine with double needle beds. They are primarily used for weaving fabric products such as Jacquard tube fabrics, sexy lingerie, shoe fabrics, 3D spacer fabrics, color strips, laces, scarves, interlock rib fabrics, medical elastic bandages, warp knitted mesh socks, color strip socks, small packaging bags and more.

Suitable raw materials:

Chemical fiber raw materials like polyester, nylon, acrylic fiber, viscose and spandex or natural fiber raw materials such as worsted cotton yarn

| Product | Raschel warp knitting machine with multi-bar |

| Needle type | Latch needle |

| Needle gauge | E22, E24, E28 |

| Working width | 2032mm (80"), 3302mm (130") |

| Number of guide bars | 4 ground guide bars, 2 Jacuqard bars |

| Form of warp let-off | Electronic positive let-off, Customized beam warping parameters (EBC) |

| Range of E-positive warp let-off | 3~30mm/course |

| Density tuning method | Digital controlled, PC touch screen operation (EBA) |

| Maximum batching diameter | 1200mm |

| Braiding method | EL electronic shogging |

| Main shaft speed | 10-600rpm (Frequency control) |

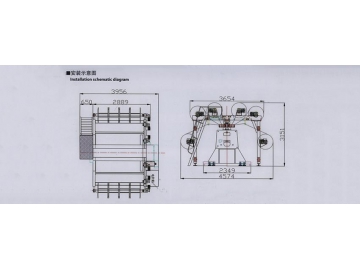

| Dimensions (L*W*H) | 3956×3654×3151 (mm) |

| Total power | 17KW |

| Total weight | Approximately 7000Kg |

| Beam size | Flange | Shaft | Aperture | Width |

| 21" | Φ535 | Φ210 | Φ152 | 540 |

| 30" | Φ762 | Φ210 | Φ152 | 540 |

Production Detail Display

Main configuration:

4 EL-drive ground guide bars.

2 sets of piezoelectric ceramic Jacuqard bars.

6 beams electronic let-off device with embedded knitting needle.

One EAC electronic traction system.

One CNC miss press structure.

German-importedGroz-Beckert latch needle.

12 inches PLC computer touch screen operation.

Servo motor with a variable frequency drive.

Transmission through closed oil tank.

Features:

1. HCRD6J2 series Jacquard warp knitting machines are a highly efficient model for producing seamless fabrics. The machines use a piezoelectric ceramic Jacquard technology and can achieve various patterns. A seamless weaving process can be done through double needle bed weaving. The fabricproducts produced using this technology are very close to the end products, which greatly reduces costs and production time of subsequent processes.

2. Guide bars are all equipped with EL-drive, which allows more patterns. Computer touch screen operation is simple, convenient and reliable.

3. HCRD6J2 series Jacquard warp knitting machines use an electronic positive warp let-off device, customized beaming parameters (EBC) and EAC electronic traction system.

4. Pattern processed with computer software, data transmission through USB.

5. Tension and density tuning are controlled through PC touch screen operation.

6. HCRD6J2 series Jacquard warp knitting machines can work perfectly and are easy to operate. Each operator can simultaneously supervise 3 warp knitting machines.

7. We provide a one-year warranty along with installation and free training.

8. HCRD6J2 series Jacquard warp knitting machines are CE certified.

9. We provide long-term sample analyzation and technical support.

Dimension figure of machine installation.

Dimension figure of machine installation.Index

fabric knitting, yarn knitting, weaving machine, warp knitting, Raschel machine, textile machine