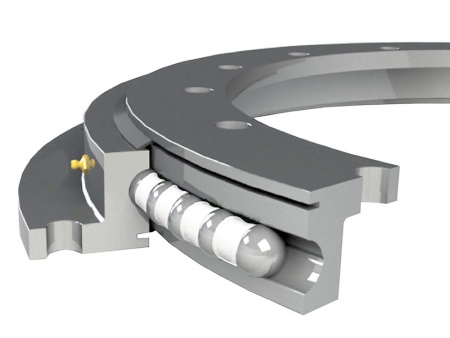

Flanged Slewing Bearing

The four-point contact ball slewing bearing with flange is designed and manufactured to accommodate more applications. This slewing bearing does not have teeth, and the inner and outer rings are flanged. It belongs to the light series of slewing bearings. Featuring flanges on the outer ring, the slewing bearings make the axial positioning simple.

Flanged slewing bearing is same in structure with other slewing bearings, featuring light weight and flexibility. There is a L-shape fringe on the outer or inner ring of flanged slewing bearings, resembling a flange. That is why it is called flanged slewing bearing.

Designed without bearing seat, the ball slewing bearing becomes more economical. In order to obtain the low friction torque, high rigidity and good rotation accuracy of the bearing, a steel ball with a small outer diameter is used. Adopting hollow shafts ensures light weight and wiring space. Flanged slewing bearings mainly bear radial loads, and they can also bear radial and axial loads at the same time.

- Range of external diameter: 100 mm to 15000 mm

- Ring material: 42CrMo / 50Mn/ C45

- Ball/roller material: GCr15

- Cage material: steel 20 or ZL102 cast aluminum alloy

- Spacer material: nylon 6 / nylon 66

- Quenching hardness of raceway: HRC55-62

- Tooth type: no gear, internal gear, external gear

- Food processing machinery

- Filling machinery

- Recycling machinery

- 1 Inner Ring

- 2 Outer Ring

- 3 Seal

- 4 Spacer

- 5 Ball/Roller

The sealing of the slewing bearing, on the one hand, is to prevent the leakage of filled grease, on the other hand, is to prevent the outside dust, impurities and moisture from invading into the exterior of the bearing and affecting its work. The sealing ring of LYJW slewing bearing is made of nitrile rubber material, which is resistant to high temperature and corrosion.

The surface of bearing raceways is quenched and the quenching hardness is HRC55-62, set to ensure its effective hardening depth.

Due to the need to transmit force, slewing bearings usually have teeth on one of the rings. The toothing is generally normalized or quenched and tempered. Depending on the application, the gears can also be full-tooth hardened or single-tooth inductively hardened. Single tooth inductively hardening can be divided into full tooth hardening and tooth foot (flanks and base) hardening.

Custom Bearings

Our dedicated team is on hand to provide help and expertise throughout the process. Whether you are ordering from our standard range of products or you want a tailored solution for your current project, they are ready to help you every step of the way.