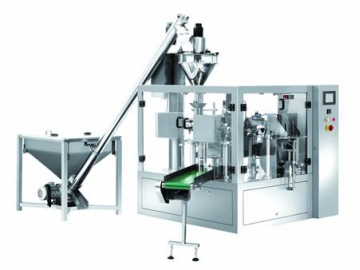

Premade Pouch Fill Seal Packaging Line for Powdered Products

Request a Quote

The premade pouch fill seal packaging line for powdered products cooperates with the screw feeder, acting as a full automatic packaging system for powdered products. This packaging line is enabled with tasks of bag feeding, bag opening, filling bag with products, product settling, heat sealing and finished package conveying. High automation greatly saves the labor cost. Therefore, this packaging line is widely used in food industry for packaging milk powder and ground coffee, as well as in pharmaceutical industry for packaging powder, pearl powder, glucose powder, etc.

Packaging bag styles - Stand-up pouch

- Top handle pouch

- 3 side seal pouch

- Paper bag

PA/PE、PET/PE、aluminum film and other heat sealable films.

Parameters| Equipment Model | MK6-200 | MK8-200 | MK6-300 | MK8-300 | ||

| Equipment Material | 304 Stainless Steel | |||||

| Pneumatic Component | SMC、AirTAC | |||||

| Vacuum Component | Vacuum Generator(SMC) | Vacuum Pump(ORION) | ||||

| Drive Mode | Frequency conversion motor drive | |||||

| Measuring Type | Auger Filler, Linear Weigher | |||||

| Operation Interface | Touch Screen(Double Language:Chinese and English) | |||||

| Bag Materials | Heat Sealable film as PA/PE、PET/PE、AL film etc. | |||||

| Bag Size | W:70~200mm L:100~300mm (Date coding requires≥140mm length) | W:160~270mm L:100~400mm (Date coding requires≥140mm length) | W:160~300mm L:100~400mm (Date coding requires≥140mm length) | |||

| Filling Range | 5~1500g | 5~2500g | ||||

| Packing Speed | 20~55bags/min(depended on the product and filling weight) | 10~40bags/min(depended on the product and filling weight) | ||||

| Package Accuracy | Error≤±1% | |||||

| Weight | 800kg | 1000kg | 1500kg | 2000kg | ||

| Dimension | 1475mm*1325mm*1480mmundefined (L*W*H) | 1635mm*1455mm*1480mm (L*W*H) | 1585mm*1545mm*1600mm (L*W*H) | 1645mm*1645mm*1640mm (L*W*H) | ||

| Total Power | 1.5kw | 2.3kw | 4kw | |||

| Driving Power Source | 380V Three-phase Five-line 50HZ | |||||

| Control Power Source | DC24V | |||||

| Compress air requirement | ≥0.45m³/min(Compress air is provided by user) | ≥0.35m³/min(Compress air is provided by user) | ||||

- Convenient operation: PLC control and human-computer interface operating system allow for intuitive and simple operation.

- Convenient adjustment: it takes only 10 minutes to change different materials.

- High automation: automatic weighing, packaging and failure alarm minimizes labor costs.

- Inspection system: Intelligent inspection to check whether the bag is fully opened. No filling and no sealing without right fill weight, saving bags and materials, as well as cost.

- Sanitary safety: Stainless steel made packaging parts ensures product cleanness and safety, in line with GMP standard.

Dust-proof and waterproof: washing with water offers simple cleaning and increased life span.

- Packaging line feeder

- Weight checker