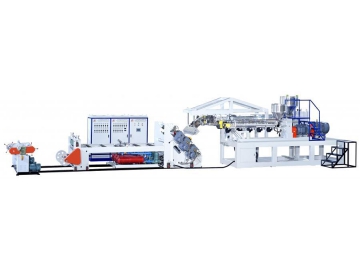

PVC Wood Plastic Foam Board Extrusion Line

PVC Wood Plastic Foam Board Extrusion Line

According to differentsheet sections, this PVC wood plastic foam board extrusion line can use a corresponding conical double extruder and allocate someauxiliary equipment like vacuum shipping benches, haul-off machines, transversesawing machines, platform to reverse materials, etc.

The extrusion production of the main engineranges from 250kg to 800kg.

Features

1. The haul-off machine in this PVCwood plastic foam board extrusion line is designed with special lift technology which is stable and reliable inoperation and has a strong haul-off force.

2. The specialenlarger cooling system for eddy is used to make the forming and cooling meetthe need of the production of different specifications of sheet.

3. Thetransverse sawing machine in this wood plastic foam board extrusion line cankeep pace with the haul-off speed of the sheet and its operation is totallycontrolled by imported PLC computer. It features reasonable design and steadyoperation. It can automatically cut with certain length and is equipped with a reclaimerfor swarf.

Applications

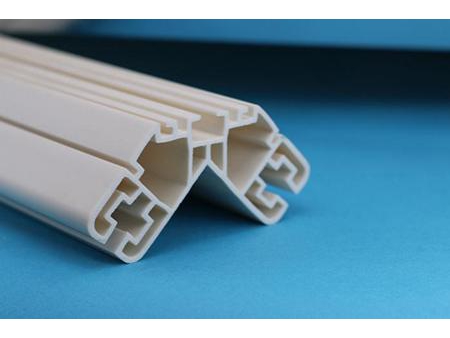

The PVC wood plastic foam board extrusion line is usedfor producing building plates wide door plates, cupboard plates, decorativematerials for the indoors or outdoors, etc.

Technical Specifications

| Specification | XD400 | XD600 | XD900 | XD1200 |

| Max. width of plate (mm) | 400 | 600 | 900 | 1200 |

| Haul-off height (mm) | 150 | 150 | 150 | 150 |

| Haul-off force (kn) | 20 | 30 | 40 | 50 |

| Haul-off Speed (m/s) | 0-3 | 0-3 | 0-2.5 | 0-2.5 |

| Auxiliary total power (kw) | 30 | 30 | 40 | 45 |

| Cooling water capacity (m3 /h) | 6 | 9 | 12 | 15 |

| Pressure of compressive air (mpa) | 0.6 | 0.6 | 0.6 | 0.6 |

As a manufacturer and supplierof PVC wood plastic foam board extrusion line based in