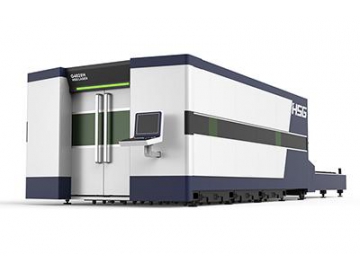

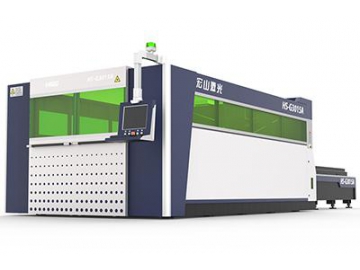

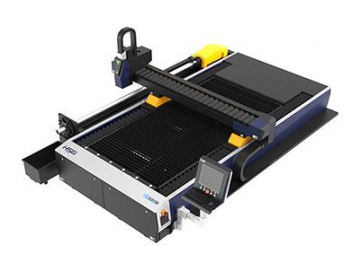

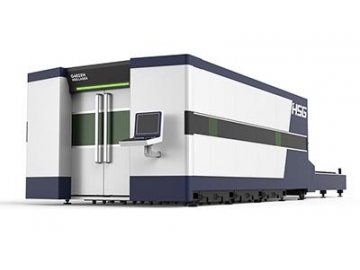

Fiber Laser Cutting Machines

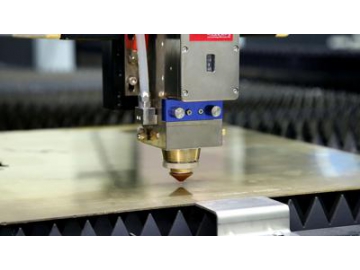

The diode pumped lasers in the fiber laser cutting machine are transmitted to the laser head using a flexible optical fiber. Because of that, this new fiber cutting way has wider processing range and higher electro-optical efficiency than traditional cutting methods.

The output power of the laser cutter varies based on the fiber laser it is equipped with, and we offer fiber lasers in a power range of 1.5kW-15kW based on customer requirements.

We have establish long-term cooperation with IPG to ensure that any fiber laser we use is of the best possible quality and stability. As a worldwide top 3 partner of IPG, we have a responsibility to offer our customers the best services from start to finish.

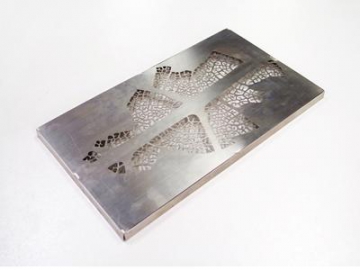

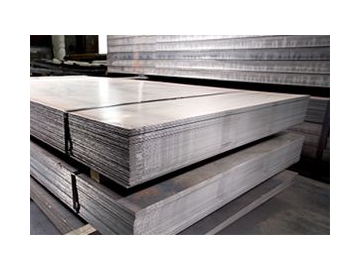

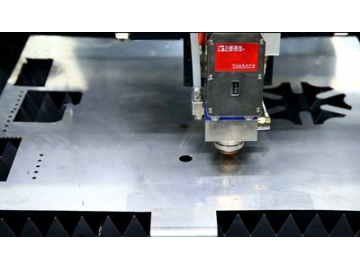

Metal sheets, tube materials, and 3D components can be processed using our fiber laser serial cutter. Not only does it feature a quick cutting speed, but it also features a good quality with smooth cut-edges and no black edges or burrs.

- The fiber can improve the softness of the machine processing simply through the transportation method of the laser.

- It features a better electric cost and cooling system thanks to the 25% photoelectric conversion.

- The disadvantage of this fiber laser is that it can be used to cut non-metallic material because of the wavelength of 1.06um which is cannot be absorbed by non-metal material.

| Items | Plasma laser cutting machine | Fiber laser cutting machine |

| Cost | High electric consumption, High cost of wearing detail maintenance, Daily maintenance cost of350RMB | Maintenance-free and no components consumption High photoelectric conversion of 30%, Save energy and protect environment suitable for bad working environment like dust, vibration, wet and high temperature, Daily maintenance cost of20RMB |

| Cutting equality | For thick plate cutting, Bad-quality beam and low cutting speed. | For both thick and medium thick plate cutting, The cutting speed is 2-3 times of that of CO2 cutter under equal working power. The cutting surface is smooth and without burrs. |

| Cutting precision | 0.1mm | Equal or more than 0.05mm |

| Principle | High temperature arc | Laser energy |

| Cutting gap | Big cutting gap | The laser beam is focused into a small spot, the cutting gap is smaller |

| Purchasing cost | lower | higher |