Paper Reel Handling System

In paper mills and corrugated board plants, paper rolls and reels are typically handled without any protective packaging. There may be a variety of safety concerns when moving paper rolls within your plant, the necessity for paper roll handling including feeding and turning securely is one of the key concerns to protect paper materials from being damaged.

Taiyang offers a selection of paper reel handling equipment and identifies roll handling solutions that are engineered to address a number of paper roll handling problems while solving the needs of paper and corrugated board manufacturers for automatic handling of paper rolls and reels, particularly in their automatic paper manufacturing plants.

Below you will find our paper reel handling systems primarily designed for paper and cardboard manufacturing plants. If you do not see your paper roll handling equipment below, please

Paper Reel Handling System

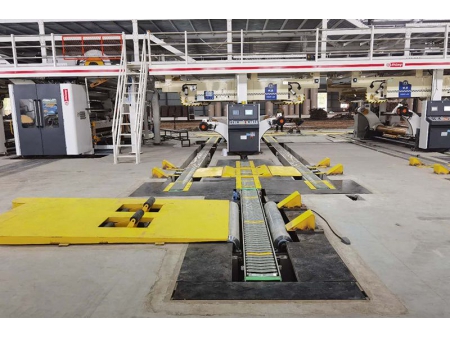

Automation of in-plant paper reel handling in Taiyang’s corrugated board intralogistics solution is realized by employing paper roll in-feed system, turntable/paper roll turning device, and reel return line. Extra efficiency can be obtained for your processes with Taiyang as your intralogistics partner.

- Paper Roll in-feed System

Temporary storage and uninterrupted in-feed

Reel preparation for the corrugator, paper reels are fed for unwinding at the right moments as preset, fully automatically in a highly efficient manner. - Turntable/Paper Roll Turning Device

Useful when reel’s transport direction requires a change

Turntable is designed for reel conveying processes where the transport direction has to be changed by 90°. Transmissions of the turning mechanism are proceeded with large and durable gears, stability and sturdiness of the turntable is thus granted. - Reel Return Line

Where rest reels get weighed and transferred

Handling the management of all rest reels, which get weighed and tagged during the process by an automated weighing unit. Real-time feedback information is available for WMS, to obtain a high efficiency for production and storage.

To serve our customers' specific needs, our team of engineers will work closely with our customers to identify the best solution by configuring different pieces of paper roll handling equipment to move paper rolls inside their paper and cardboard plants.

1. Chain bar: Chain bar pitch: 63.5mm

2. Slat: V type, size 250*55*8 mm, made of 15Mn steel

3. Motor: Shaft speed reducer drive with helical gear

4. Capacity: 200kg/m (space between paper rolls: 500mm)

5. Speed: 60 rolls/hour

1. Feed paper roll to different reel stand.

2. Mode: Pneumatic

3. Function for storing paper roll: optional

1. Stop moving paper roll slowly

2.Control mode: Automatic

1. Push the paper roll carefully onto the next conveyor.

2. Control mode: Automatic