Types of Non-Woven

Nonwovens are divided into categories named for their production techniques:

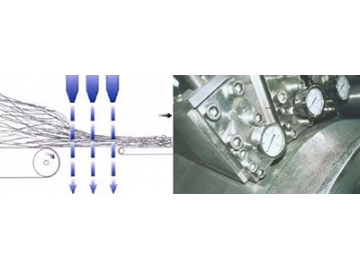

Spunlace Nonwoven FabricSpunlace nonwoven fabric is produced using a spunlace technique based on the usage of water needles to entangle the raw fiber materials.

Features:- Maintains the original characteristics of the fibers

- Looks and feels similar to standard textiles

- High strength, good mechanical performance, and aesthetic properties

- Minimal fluffiness

- Excellent hydrophilic performance

- High absorbency

- No adhesive reinforcement

Wipes, surgical drapes, surgical gowns, bandages, protective clothing, decorative fabric, linings, masks, facial puffs, etc.

Thermal Bonded Nonwoven FabricThermo bonded nonwovens are manufactured by utilizing high temperature and pressure calendering rollers. Nonwoven fleece undergoes a calendering process that involves the simultaneous application of high heat and pressure that combines the loose fibers into a tightly compacted fabric.

Features:- Thin and lightweight

- Good draping ability

- Adequate strength

Baby diapers, pads, napkins, masks, lining fabric

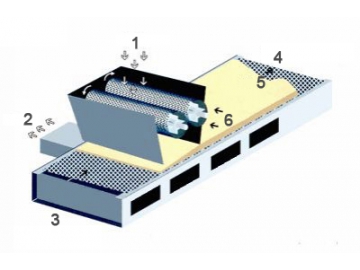

- Air in

- Air out

- Moving wire mesh

- To further bonding

- Web

- Fibers

Drylaid nonwovens are made using drylaid web-forming technologies including carding and garnetting to convert loose fibers into a sturdy web. In the drylaid process, web formation fibers are manipulated in a dry state and then bonded by mechanical, chemical, or thermal bonding methods.

Features:Fluffy and soft with strong moisture absorption properties.

Recommended Applications:Medical and hygiene materials, especially disposable hygiene products (baby diapers, pads, wipes)

- Binder impregnation

- Fiber and water slurry

- Extracted water

- Web making

- Drying

- Wind up

Wet-laid nonwovens are manufactured using a hydrodynamic process similar to the wet processes used in papermaking. The wet-laid process features a filtration plant in which fibers are suspended in a revolving drum-like sieve. This creates ideal conditions for producing a homogenous length of fabric as the fibers suspended in the water are evenly dispersed. The fibers are then pressed together to expel the moisture and create a high quality, nonwoven fabric.

Features:- High strength with excellent heat, water, and chemical resistance

- Great flexibility

- Outstanding insulation performance

- Good printing performance

- High dimensional stability

- Specialty paper: tea bags, filter papers

- Industry: filters, insulating materials

- Medical: medical tapes, procedure packs

- Household: wallpapers

- Polymer chips

- Extrusion die

- Extruder

- Filament attenuator (cooling and stretching)

- Fiber dispersion

- Laydown

- Bonding

- Wind up

With spunbond nonwoven fabrics, filaments or fibers are spun in a similar fashion to standard threads but with an added melt or solution aspect. This is performed on thermoplastic raw materials directly in the spunmelt process. Molten polymer granulate is fed into a spinning jet and the emerging thread or filament is drawn out by air or mechanically and thereby stretched. The filaments are laid out in circular rows where even, multi-directional properties are achieved.

Features:- Excellent elasticity

- Many reinforcing method options

- Excellent thermal properties

- High dimensional stability

- Inherently UV stable

- Good permeability

- PP: geotextiles, medical and hygiene materials, carpet backings

- PET: filtration materials, linings, agricultural materials, wraps, carpet backings

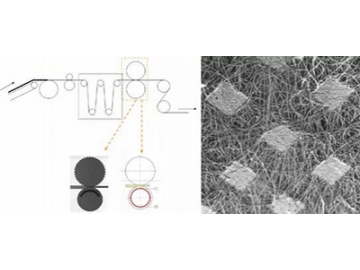

Melt-blown Nonwoven Fabric

Meltblown nonwovens are formed from fibers that are smaller in denier (usually measured on the order of microns) than those found in other nonwovens or textiles.

- Excellent uniformity with a soft feeling

- Low to moderate web strength

- Good insulation and filtration

Filtration media, medical fabrics, substrate for synthetic leather, adsorbents, liner fabric for electronic products

Needle Punching Nonwoven Fabric

Needle punching nonwovens are mechanically formed by a method called carding, which uses machines with rotating cylinders on which raw fibers are laid out in a broad web. This method allows for different directional orientation and heavier articles can be produced with several layers. After this, needling as well as bonding and compression are carried out, resulting in high-quality nonwoven fabrics.

Features:- Excellent dimensional stability and elasticity

- Higher thickness than some other nonwovens

- Good permeability and high filtration

- Soft and fluffy