Radio Frequency Generator

Features of the Radio Frequency Generator

1. With over two decades of practice and application, our radio frequency generator or high frequency generator has a more scientific and reasonable circuit design that is more convenient to use, along with a user friendly operation panel.

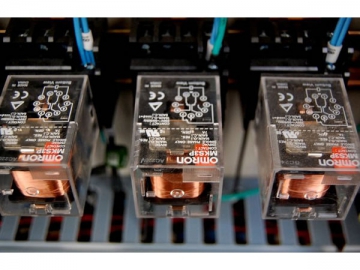

2. Control components such as the relay and contractor are all from internationally known top brands.

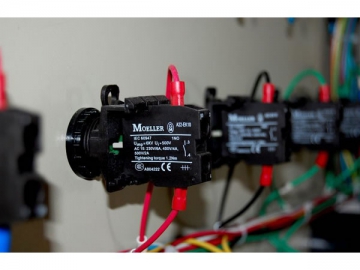

3. Indication and control parts such as light and switches are also from internationally known brands.

Principles of the Radio Frequency Generator

The RF generator boosts and rectifies 380 volts of power sources and converts them into high frequency electric fields via an electronic tube and oscillation circuit. The high frequency electric field will then be transmitted to the load where water or glue molecules can instantly be polarized under a high frequency of 6.78 MHz.

Polarized water and glue molecules can move at super high speeds along the change in the electric field and generate heat from friction, making a better heating, bonding and drying process.

Technical Parameters of the Radio Frequency Generator

| Model | ||||||

| Power | 20KW | 30KW | 40KW | 50KW | 80KW | 100KW |

| 1.5KW-100KW | ||||||

| Frequency | 6.78MHz, 13.56MHz, 27.12Mhz | |||||

| Cooling type | Air cooling | Water cooling | ||||

| Protection | Overload, door switch, over heating, air pressure protection etc. | |||||

Why Radio Frequency Generator?

1. Fast

Because high frequency is an electric field that can penetrate wood pieces and directly heat the water or glue molecule, heating efficiency is improved. When compared to a conduction heating method, radio frequency heating is better, especially for thicker pieces.

2. Uniform

The high frequency ensures a uniform heating. High frequency electric fields only act on water or glue molecules so that it can uniformly spread in the molecular area, making sure the water or glue evenly absorbs the heat energy.

3. Controllable

The heating process is controllable, when the power is on, heating occurs. When the power is off, heating stops.

4. Selective

High frequency dielectric heating is selective. Different materials have different dielectric loss coefficients and different energy levels that they can absorb. Due to this, machines equipped with radio frequency generator selectively heat material in the electric field to improve efficiency and reduce energy consumption.

5. Others

When the heating device pauses or stops, the counter electrode remains in a cooling state, considerably improving the operating environment.

The high frequency generator can kill bacteria and worms in wood pieces and generates no smoke or dust, making it environmentally friendly.

Applications

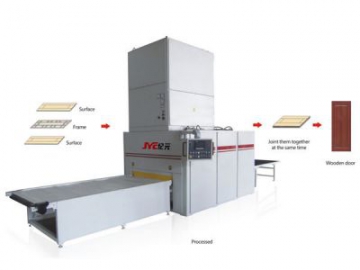

Any integrated high frequency heating device is provided with a high frequency oscillation source. When equipped with a radio frequency generator with a different power, it can meet technological requirements for heating various work pieces.

1. Multi-layer Board and MDF board gluing

This HF generator can be sued for gluing various wood boards together, including bent wood for chairs, sofas, headboards, bed frames cabinet doors, engineered wood and furniture frames.

2. Wood board jointing and gluing

Radio frequency system is suitable for laminated wood jointing, furniture board and batten edge banding, door pocket and L shaped wood door edge banding, door frame jointing, cabinet door assembly and furniture frame gluing.

3. Moisture drying

The radio frequency generator can carry out drying processes in wood, grain, food and textiles.

4. Special industries

Applicable industries include tobacco, grain worm killing, environmental protection and printing.

Parts Figure