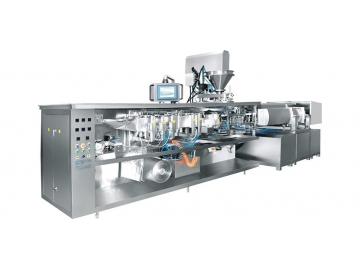

JDZ-120/160/240 Rotary System Pouch Packaging Machines

The JDZ-120/160/240 series rotary system pouch packaging machines feature a vacuum function to keep air out, and avoid food oxidation and spoilage. This series is applicable for packaging jam, conserves, coffee and more.

If you prefer machines for packaging food, we recommended to choosing the 20/160/240 series.

In addition, the JDZ-120/160/240 series is used for packaging pharmaceutical materials, cosmetics, condiments, facial masks and more.

1. Film Unwind

2. Bag Forming

3. Film Guide

4. Photocell

5. Bottom Seal

6. Vertical Seal

7. Tear Notch

8. Cutting

9. Pouch Catching

10. Pouch Opening

11. Filling Ⅰ

12. Filling Ⅱ

13. Top Seal

14. Finished Product

15. Product Outlet

| Type | Minimum Bag Size (mm) | Maximum Bag Size (mm) | Packing Capacity (ml) | Packing speed (ppm) | Power (kw) | Gas consumption (NL/min) | Weight (kg) | Equipment Size (mm) |

| JDZ-120 | 70*90 | 90*120 | 50 | 100-120 | 15.5 | 0.6 | 4200 | 5500*1300*2800 |

| JDZ-160 | 80*100 | 150*160 | 200 | 60-80 | 13.2 | 0.5 | 3500 | 5000*1300*2800 |

| JDZ-240 | 80*110 | 180*240 | 500 | 60-80 | 18.5 | 0.6 | 4000 | 6000*1300*2800 |

· Film Unwind Unit

· User-friendly design, quick and easy to change films

· Ensure good control of film tensile force

· More flexible and suitable for different pouch specifications· Dual Filling Station

· Reduce filling time by half

· Improved filling accuracy

· Fill 2 products simultaneously· Servo WB Structure

· Accurate positioning with stable operation

· Good rigidity, big load bearing

· Long WB moving distance