Parts and Consumables

Request a Quote

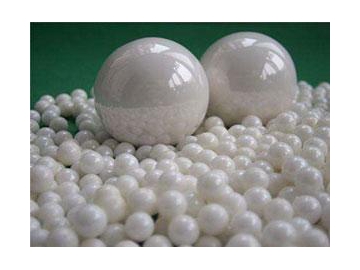

- The appearance of grinding ball is a white ball, with 0.5-120mm diameter and 70%-99% alumina content, which can be produced according to customers’ requirement.

- Chrome steel grinding ball can separate and grind materials, which is used in slurry of various kinds of bead mills and ball mills. The grain diameter of them is between 0.5mm to 150mm. The chrome content and ball size can be customized according to customers’ requirements.

- The zirconia grinding ball is made of nano-sized zirconia powder by iso-static pressing and high temperature sintering. Three is no pore and cavity in the ball and the inner of the ball forms homogeneous compact and stable quadrangle zirconia crystal structure(Ce-TZP), which has the same hardness, density and abrasion resistance like gemstone.

- Silicon oxide grinding ball is made of high purity and fine talc ceramic powder by rolling, isostatic pressing and high temperature roasting. Silicon oxide ball is a economical type grinding ball with two choice of sphere and cylinder.

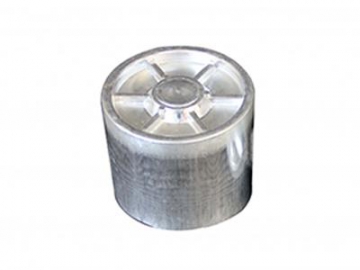

- We can customize ball mill liner for customers, whose hardness is more than HRC45-55, impact toughness is over 25J and service life is two times than common liners.The function of wearable liner is to prevent the cylinder body from being directly hit by grinding media and materials and corrosion and wear of slurry.

- We can provide customers with customized ceramic ball mill liner. The function of ceramic ball mill liner is to resist the impact on the inner side of the cylinder during the grinding process, so as to reduce the wear on the equipment units.

- We provide customers with customized rubber ball mill liners. The density of these wear resistant rubber liners is about 1/6 that of steel rubber liners, which reduces the cylinder weight, which in turn reduces the motor load during operation.

- We can provide customers with customized wear resistance overlay welding plate. These wear-resistance accessories including crusher hammerhead, discs on the rotor shaft, impact plate and so on. The highest surface hardness of wear resistance overlay welding plate can be more than HRc65.

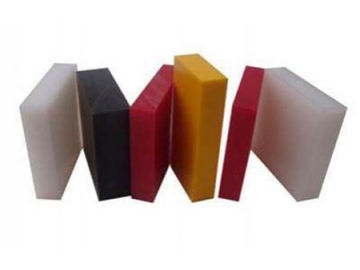

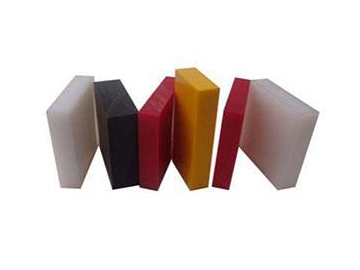

- UHMWPE plate and pipes are products made using an engineering plastic that features an outstanding performance at low temperatures. This material has an excellent shock resistance, and wear resistance, as well as great self-lubricating abilities.

Vostosun is a dynamic Chinese enterprise, offering customers mineral processing equipment of all kinds and capabilities. We provide crushing equipment, mineral feeding equipment, conveying equipment, washing equipment, powder grinding equipment, and much more. Whatever mineral processing needs you may have, Vostosun has the solution.

Related products

Send Message

Most Recent

More

Other Products

Videos