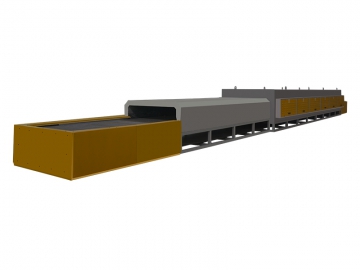

Mesh Belt Furnaces for Continuous Heat Treatment

Request a Quote

Application

Mesh belt furnaces for continuous heat treatment can be customized to realize various processes including quenching, annealing, tempering, aging, normalizing, curing, etc. This product can be designed for manufacturing different kinds of products such as hardware tools, glass products, ceramic products, motorcycle parts, plastic hardware, fasteners, chains, bearings, latches, according to your requirement.

Features

- The temperature is controlled using a microcomputer intelligent temperature controller and heating is automatically controlled using a thyristor to achieve PID control.

- Conveyance is completed using a high-temperature stainless steel mesh belt with frequency stepless speed control and a rapid temperature rise.

- The furnace is manufactured in segments to facilitate both lifting and transportation.

- The is suitable for continuous mass production.

Parameters

- Rated voltage: three-phase 380V

- Frequency: 50HZ

- Rated temperature: normal temperature ~ 650 ℃ (adjustable)

- Rated power: 210KW (adjustable when such high power is not required)

- Working size: the total length is 18000mm, the lengths of feeding area, heating area, cooling area, and discharging area, respectively, are 2000mm, 9000mm, 4540mm and 2500mm

- Temperature control accuracy: ±3℃

- Heating element: resistance wire made of 0Cr27Al7Mo2

- Wiring method: Y-Y-Y type

- The mesh belt and motor are controlled using a stepless speed regulation inverter with an operation range between 0-500mm/min.

- Equipment weight: 4500kg

Furnace material

- The furnace casing is a frame welded using 60 x 60 square tubes and 6# angle iron, with the outer cover welded with a 4mm thick steel plate.

- The conveyor belt is a SUS304 stainless steel mesh belt with a wire diameter of 3.0mm and a hole distance of 10 x 15mm.

- The drive mechanism uses a Dongguan motor cycloidal pin reducer that is 2.2kg in weight. Drive control is achieved via a sprocket and chain, while the mesh belt running speed is adjustable under frequency control.

- The furnace is filled with an all-fiber structure, which absorbs less heat, saves energy, and quickly heats the furnace. It should be kept clean to prevent dust and debris from falling into the furnace and impacting product quality.

- The heating element is vertically installed in a ceramic tube running throughout the furnace.

Electrical control system

- The electrical control cabinet is a vertical independent electric control cabinet with the instrument panel as the inner door and transparent glass as the outer door, ensuring it effectively prevents instruments and electrical appliances against external dust. The control cabinet is 1000mm wide, 1600mm high, and 450mm thick.

- The temperature is controlled by 6 digital display intelligent temperature controllers for an automatic temperature control and heating in 6 zones.

- The furnace is equipped with a 3-phase operating current, voltage display, leakage protection, over-temperature alarm and other safety features.

- The heating element is controlled by 6 adjustable power thyristor sets, ensuring an energy saving, environmentally friendly performance and accurate temperature control.