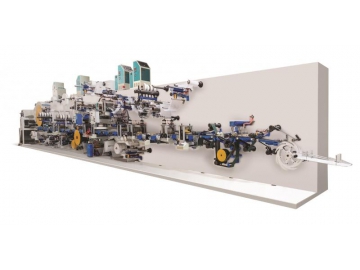

RL-YNK-300, Production Line for Baby Diaper

Request a Quote

RL-YNK-300, Production Line for Baby Diaper

Description RL-YNK-300 baby diaper production line is specially designed to produce baby diapers, which consists of frontal tape, side tape, standing leak guard, leg cuffs, etc. This production line is able to make large, medium and small sized baby diapers, with an output of 300-400 pcs/min.

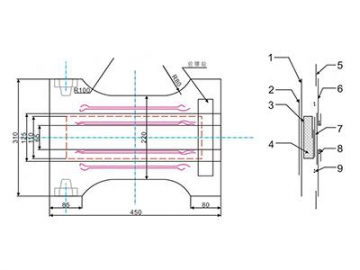

Baby diaper design- Polyethylene(PE) Film

- Frontal tape

- Tissue

- Wood pulp+SAP

- Side tape

- Hydrophobic nonwoven

- Acquisition layer

- Leg elastics

- Elastics

- Finished products are tri-folded and stacked in a line.

- Dosing applicator of super absorbent polymer.

- The production line equips a high efficiency pulverizer.

- Inverter control system offers high precision control.

- PLC system with touch screen control is easy to operate.

- Transmission system consists of sealed gearbox, universal coupling and synchronous belt, offering stable transmission and good synchronism.

- Automatic raw material applicator and unwinder, controlled by constant tension.

- Automatic detection for broken material and lacking of material, and alarms automatically.

- Automatic rejection system for changing and splicing materials.l

- Molding and positioning process is equipped with an electronic differential to conduct synchronous regulation without closing down.

- Production speed: 300-400 pcs/min

- Product size: to customers’ demand

- Equipment size: 23000mm×3500mm×2800mm

- Power supply: three-phase 380V, 50HZ

- Weight: about 30T

- Power: ≈120 kW (glue applicator and air compressor excluded)

- Operators: 2-3

Note: Above data is provided for reference only and it depends on your customized demands.