Built-in Rotary and Vibrator Hose Type:NJG-SZ / NNG-SZ

Request a Quote

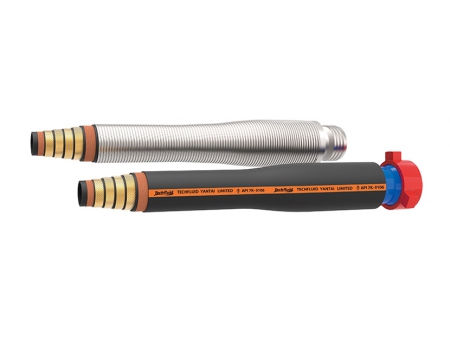

The built-in rotary hose is the flexible connection between the drilling machine and the water faucet for vertical movement, as shown in the following picture.

The vibrator hose is a flexible connection between the slurry pump and the vertical pipe with an exceptional vibration absorption.

Production Standard:

API Spec 7K / ISO 6807 / GB/T 24145

API Standard:

7K-0458

Temperature Range:

Ⅱ级 , -25 至 100 ℃

Fire Protection Requirements:

The normal hose structure meets SR6A standards and is able to maintain for up to 5 minutes in a 704℃ fire. The outer cover can be equipped with an added fire insulation layer (glass fiber cloth) which meets SR6B standards for fire protection and maintains up to 30 minutes in a 704℃ fire.

Construction:

- Composite rubber as the inner sealing tube, mainly composed of nitrile rubber with an excellent oil, seawater, and thermal resistance.

- Protective layer made of a high strength fabric cloth

- Skeleton material made of a high strength helix steel wire

- Composite rubber cover layer, made of a chloroprene rubber for an outstanding fire protection, oil, abrasion, ozone, and aging resistance.

- Optional electric heating tracing feature

- Optional stainless-steel armored cover, stainless steel wire, and polyethylene helix cover according to specific requirements

- Flexibility Level: FSL2

- Maximum Length: 70m

- Production Length Tolerance: 6.4m or under ± 64 mm, above 6.4m ± 1%

- The minimum bending radius is measured according to the hose central line

| Code No. | API Level | I.D. (inch) (mm) | O.D. (inch) (mm) | Working Pressure (bar) (psi) | Test Pressure (bar) (psi) | Flame Shield | Safety Factor | FSL | MBR (storage) (m) | MBR (operation) (m) | Weight (Kg/m) | Max. Length (m) | |||||

| NJG-SZ-51×34.5 | D | 2 | 51 | 3.58 | 91 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 0.8 | 0.9 | 11.24 | 70 | |

| NNG-SZ-51×34.5 | D | 2 | 51 | 4.17 | 106 | 345 | 5,000 | 517 | 7,500 | Yes | 2.5 | FSL2 | 0.8 | 0.9 | 15 | 70 | |

| NJG-SZ-64×34.5 | D | 2.5 | 64 | 4.06 | 103 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 0.8 | 0.9 | 13 | 70 | |

| NNG-SZ-64×34.5 | D | 2.5 | 64 | 4.65 | 118 | 345 | 5,000 | 517 | 7,500 | Yes | 2.5 | FSL2 | 0.8 | 0.9 | 16 | 70 | |

| NJG-SZ-76×34.5 | D | 3 | 76 | 4.72 | 120 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 1.1 | 1.2 | 18 | 70 | |

| NNG-SZ-76×34.5 | D | 3 | 76 | 5.28 | 134 | 345 | 5,000 | 517 | 7,500 | Yes | 2.5 | FSL2 | 1.1 | 1.2 | 20 | 70 | |

| NJG-SZ-89×34.5 | D | 3.5 | 89 | 5.28 | 134 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 1.2 | 1.3 | 21 | 70 | |

| NNG-SZ-89×34.5 | D | 3.5 | 89 | 5.75 | 146 | 345 | 5,000 | 517 | 7,500 | Yes | 2.5 | FSL2 | 1.2 | 1.3 | 25 | 70 | |

| NJG-SZ-102×34.5 | D | 4 | 102 | 6.3 | 160 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 1.2 | 1.4 | 35 | 70 | |

| NNG-SZ-102×34.5 | D | 4 | 102 | 6.8 | 173 | 345 | 5,000 | 517 | 7,500 | Yes | 2.5 | FSL2 | 1.2 | 1.4 | 38 | 70 | |

| NJG-SZ-127×34.5 | D | 5 | 127 | 7.52 | 191 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 1.4 | 1.5 | 51 | 70 | |

| NNG-SZ-127×34.5 | D | 5 | 127 | 8.07 | 205 | 345 | 5,000 | 517 | 7,500 | Yes | 2.5 | FSL2 | 1.4 | 1.5 | 56 | 70 | |

| NJG-SZ-152×34.5 | D | 6 | 152 | 8.82 | 224 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 1.6 | 1.8 | 57 | 70 | |

| NNG-SZ-51×51.7 | E | 2 | 51 | 4.06 | 103 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.1 | 1.2 | 19 | 70 | |

| NJG-SZ-64×51.7 | E | 2.5 | 64 | 4.88 | 124 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.1 | 1.2 | 28 | 70 | |

| NNG-SZ-64×51.7 | E | 2.5 | 64 | 5.35 | 136 | 517 | 7,500 | 776 | 11,250 | Yes | 2.5 | FSL2 | 1.1 | 1.2 | 31 | 70 | |

| NJG-SZ-76×51.7 | E | 3 | 76 | 5.43 | 138 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.2 | 1.3 | 31 | 70 | |

| NNG-SZ-76×51.7 | E | 3 | 76 | 5.98 | 152 | 517 | 7,500 | 776 | 11,250 | Yes | 2.5 | FSL2 | 1.2 | 1.3 | 35 | 70 | |

| NJG-SZ-89×51.7 | E | 3.5 | 89 | 5.94 | 151 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.3 | 1.4 | 38 | 70 | |

| NNG-SZ-89×51.7 | E | 3.5 | 89 | 6.57 | 167 | 517 | 7,500 | 776 | 11,250 | Yes | 2.5 | FSL2 | 1.3 | 1.4 | 42 | 70 | |

| NJG-SZ-102×51.7 | E | 4 | 102 | 6.61 | 168 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.4 | 1.5 | 44 | 70 | |

| NNG-SZ-102×51.7 | E | 4 | 102 | 7.17 | 182 | 517 | 7,500 | 776 | 11,250 | Yes | 2.5 | FSL2 | 1.4 | 1.5 | 50 | 70 | |

| NJG-SZ-127×51.7 | E | 5 | 127 | 8.03 | 204 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.5 | 1.6 | 64 | 70 | |

| NNG-SZ-127×51.7 | E | 5 | 127 | 8.58 | 218 | 517 | 7,500 | 776 | 11,250 | Yes | 2.5 | FSL2 | 1.5 | 1.6 | 69 | 70 | |

| NJG-SZ-152×51.7 | E | 6 | 152 | 9.76 | 248 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.6 | 1.8 | 92 | 70 | |