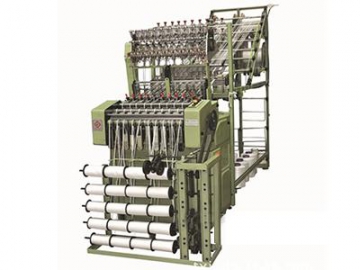

Double Decker Needle Loom

Request a Quote

- TXF 10/25

- TXF6/80

With the webbing width range of 1mm to 25mm, the double decker loom is known for its exceptionally high productivity. It carries out the production of two layer webbing, with a maximum of 20 weaving heads.

Parameters

| Model | Heads / lines | Max. width(mm) | Heald frame | Pick pepeat | Weft density(cm) | Machine rotation speed(r/min) |

| D10/25 | 10-20 | 25 | 12(16) | 8-48 | 3.5-36.7 | 1000-1200 |

Optional devices

- Three roller automatic rubber feeding device

- Double roller automatic rubber feeding device

- Double take off wheel device

- Double take off roller device

- Automatic weft feeding device

- Belt weft feeding device

- Double weft double latch needle device

- Double hook and double latch needle device

- Frequency converter

- Counter

- Front / rear automatic take-up machine

- Rear creel number

Features

- The compact and advanced machine structure ensures the needle loom features a small footprint.

- Main parts are produced using CNC equipment with a process precision of 0.005mm, ensuring machine durability and reducing the depreciation rate, offering more benefits to the user.

- Lubrication is carried out using an automatic-circulation lubrication system. A broken yarn automatic stop function provides effective control over fabrics used while saving both time and labor.

- The yarn feeding device utilizes a belt transmission with a gear for flexible speed shifting. This ensures weft yarn feeding stability and ensures the machine is suitable for the production of a variety of webbing types.