Gypsum Board Sheathing

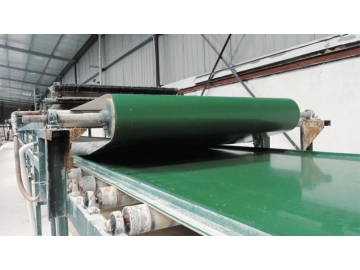

Gypsum board sheathing unit consists of forming belt, special forming machine, conveying roller path and edge cleaning device. Gypsum board sheathing procedure takes great importance in a paperless drywall plant.

Unlike plasterboard, external binding force is required in the initial setting process during the production of paperless drywall to get the required shape.

Main device in gypsum board sheathing unit consists of bottom belt forming structure and upper belt closing structure.

Bottom belt forming structure:Edges of bottom belt are tilted to keep slurry in during the forming process. Big-diameter rollers are applied for driving pulleys, to increase bending radius of the belt, granting it better durability.

Upper belt closing structure:Liftable design is applied in belt pulley, to satisfy various shaping requirements, and place internal mesh in parallel, ensure an even mechanic property.

Belts are made of advanced new material, a cleaning device is deployed in its procedure; Multiple automatic adjusting devices are set to ensure the thickness of the product, so that the product reaches its best mechanical performace.