Pulp Bowl Forming Machine

Application

Pulp bowl forming machine can translate plants fiber (sugarcane pulp, bamboo pulp, wheat straw pulp, reed pulp, wood pulp) into food bowl. The produced bowls are suit for microwave oven, oven, frozen, and distillation. Besides, the package can be used in the fields of industrial and domestic.

Our pulp bowl forming machine can be matched with different molds to produce different pulp products. Six types of equipment are optional; you can click the links below to check:

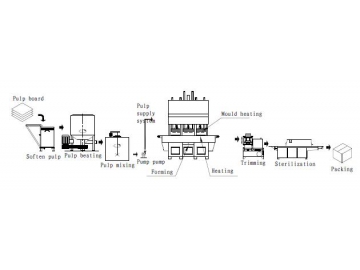

Analysis of production process

The process can be mainly divided into four steps.

1. First of all, translating pulp board into pulp liquor. The pulp board, after being reduced by hydraulic pulping machine, will come into slurry mixing tank to be mixed with food grade waterproof and anti oil additive before coming into slurry tank. The slurry delivery system will grout accurately and quantitatively, do hydraulic agitation homogenate, vacuum dehydration and molding.

2. Then, molding process. It’s a vital process contains quantitative slurry feeding, back flushing hydraulic homogenization and vacuum adsorption dehydration molding.

3. After molding, the tableware blank is transferred to the hot pressing solidification mold, and then dehydrated, dried and solidified. After that, mechanical hand will remold the collection to finish the process.

4. Finally, finalizing process. Manipulator will transfer the product to the hot pressing solidification mold, after drying and shaping products are carried out to sterilize and package.