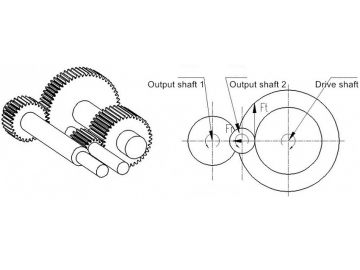

Counter-Rotating Twin Screw Extruder

Request a Quote

This product has been discontinued and removed from our shelves.

Omega provides our customers with counter rotating twin screw extruders that are capable of directly extruding sheet products. This extruder is ideal for extrusion of powdered PVC and other heat sensitive plastics, which not only offers a gentle shear force to prevent overheating, but also allows for an easy transportation.

Advantages

- Utilizing advanced technology, the unique screw design features a uniform plasticization, stable operation, and high output.

- The barrel is heated with copper winged ceramic heaters or cast aluminum heaters. The barrel cooling is done via air, ensuring an excellent heating and cooling effect, as well as accurate temperature control.

- The screw core uses external circulation or internal circulation temperature control systems to avoid material over-plasticization due to a higher capacity.

- The vacuum exhaust system is used in the barrel mixing section, allowing it to discharge moisture and volatile gas from the material, and improve product quality.

- Suitable for powdered PVC and other thermal sensitive material processing.

- Users can choose from a variety of electric control systems, including a thermostat switch system, or a PLC automation control system, where the production is stable, control is simple, and operation is easy.

Parameters

| Model | Screw Diameter (mm) | L/D Ratio | Max. Screw Speed (rpm) | Main Motor Power (kW) | Max. Output (kg/h) |

| SJP75-28 | φ75 | 28:1 | 36 | 37 | 220~250 |

| SJP93-28 | φ93 | 28:1 | 36 | 55 | 340~380 |

| SJP110-28 | φ110 | 28:1 | 36 | 75 | 420~460 |

| SJP120-26 | φ120 | 26:1 | 36 | 110 | 520~560 |

| SJP130-26 | φ130 | 26:1 | 36 | 132 | 640~680 |

Related products

Send Message

Most Recent

More

Other Products

Videos