Calibrating and Sanding Machines Woodturning Sanders for Surface, Edges and Profiles

Mingda provides a variety of calibrating and sanding machines used to smooth and polish wood surfaces to emphasize wood’s natural beauty. This equipment is widely used in furniture, construction, decorative materials, artwork and more. Each is durable, fast, efficient, and saves labor. Our calibrating and sanding machines include a wide belt sander series and brush sander series used to simultaneously process single side, double sides, or four sides of a variety of woodware or irregularly shaped woodwork pieces.

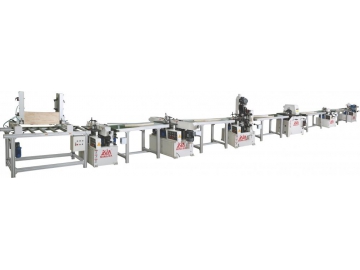

Sanding LineWith the use of automatic wood sanders and auxiliary equipment, we established a complete sanding and calibrating line for a higher efficiency. Shown here is our classic sanding line as an example.

- Mingda’s double sided wide belt sanders simultaneously process double sided woodwares to achieve a completely smooth surface. These sanders are applicable to a wide array of wood materials, including solid wood panels, plywood panels, particle board, MDF panels, OSB panels, wood-core plywood, and more.

- The 4-sided brush sander is equipped with durable sanding brushing, making it ideal for processing different irregular wooden workpieces and finishing a super fine sealer sanding. It is especiallysuitable for processing long strip shaped irregular workpieces, such as the surfaces of dining room tables and chairs for a smooth, fine surface.

- Mingda double sided brush sanders can process both the left and right sides or top and bottom sides of three dimensions wood pieces at the same time to achieve completely smooth surfaces.

- Edge sanders are used to process different, irregularly shaped wooden workpieces and sand their edges. They are especially suited to processing long strip workpieces like dining table legs and chair legs. After workpieces have been shaped, this sander will carry out sanding to achieve round, smooth, and perfect edges. PLC controlled, this sander is easy to operate, learn, and adjust. It is capable of sanding different edges according to different materials, adjusting the edges within 1 to 3mm.

- Mingda provides belt conveyors with an exceptional loading and conveying stability. These conveyors are part of a full woodwork assembly line. Shown below is a standard size, and feel free to reach out to us for customization information.

We also provide customized calibrating and sanding machines according to customer requirements. With our foundation in 2002, we have extensive experience and utilize core techniques and components imported from Taiwan, as well as other internationally known manufacturers. Other components are made using a highly precise CNC machine for the manufacturing of calibration and sanding machines, allowing us to odder our clients high quality and cost-effective equipment to optimize their production processes with highly customized solutions. No matter what your needs are, please do not hesitate to for a free consultation.