Draw Heat Setting Winder

Request a Quote

The draw heat setting winder is widely applied in the drawing and setting of strongly twisted yarn products like industrial yarns and advanced sewing threads. It can effectively improve the properties of the yarn like elongation, shrinkage and tenacity, and eliminates various yarn faults caused by the unevenness, declined tenacity and incomplete setting of the over-twisted yarns caused by traditional techniques.

Features

- Cross heat setting device with double rollers that can effectively eliminate the stress of the yarn, making the yarn reach specified elongation and tension without loop tendency, thus the yarn can be straighter.

- This yarn winding machine is driven by a long-axial brushless DC motor to save energy. And the winding and drawing roller is controlled by independent motor.

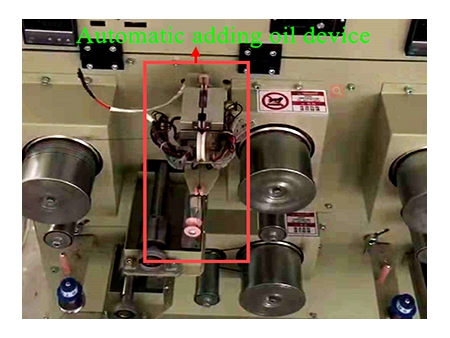

- This machine features various advanced functions such as length measuring by electronic frequency converter, auto-shut down at yarn breaking, auto-shut down at full winding, heat setting, yarn oiling, etc.

- The wrap angle of the creel and the back pressure are adjustable. The device can be balanced by the weight of pneumatic creel to keep the pressure constant and the winding densities uniform between inner and outer yarn layers.

- The grooved drum can be made of nickel-phosphorus alloy with the characteristics of high wear resistance, high corrosion resistance and high cohesion.

Parameters

| Machine speed | 25-600 m/min |

| Traverse length | 200mm, 250mm |

| Package diameter | ¢290mm |

| Way of anti-overlapping | By electronic |

| Package weight | 10 kg |

| Automatic length fixing | Automatic length fixing, up to 999999m |

| Dimensions | 1120 * 730 * 1740mm |

| Weight | 230 kg |