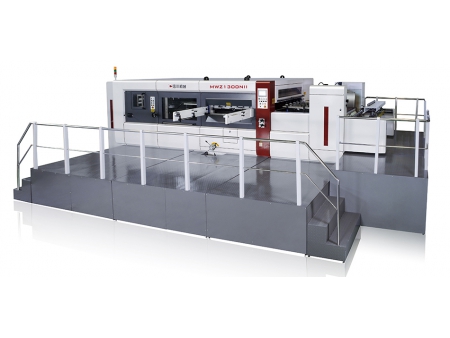

Automatic Flatbed Die Cutter, MWZ 1300Nii

MWZ 1300Nii automatic flatbed die cutter is featured by a maximum cutting size of up to 1300 x 960mm, and capable of cutting 5000 sheets per hour. It is an ideal converting machine for manufacturers who require precise die-cutting of corrugated boards, laminated paperboards, carton boards and corrugated plastic sheets.

| Machine model | MWZ 1300Nii |

| Max. sheet size | 1330 x 980mm |

| Min. sheet size | 550 x 480mm |

| Max. cutting size | 1300 x 960mm |

| Cutting force | Up to 250tons |

| Max. mechanical speed | 5000 sheets per hour |

| Height of cutting rule | 23.8mm |

| Pressure adjustment | ±1.5mm |

| Cutting precision | ±0.5mm |

| Min. front waste | 10mm |

| Chase size | 1330x980mm |

| Power consumption (without air pump) | 29kW // 380V, 3-PH, 50/60 Hz |

| Machine dimensions | Length: 9500mm |

| Width: 5560mm | |

| Height: 2600mm | |

| Machine weight | 22 Tons |

- Standard Lead Edge Feeder

Lead edge feeder offers high speed precise sheet feeding.

- Feeding Table

Left and right side push lays ensure accurate alignment and power registration.

Servo driven conveyor transfers sheets to the die cutter accurately and efficiently. - Stripping Section

Central positioning system simplifies stripping die set-up and allows fast job changeover

Heavy duty double action stripper efficiently removes waste, male and female stripping tools can accommodate various stripping tasks.

The waste separator at front removes trim waste from the sheet and transfers it to the machine drive side by conveyor belt. - Die Cutting Section

Central positioning system allows fast job changeover and easy machine set-up.

Independent automatic self-lubrication system ensures smooth running while reducing maintenance job.

Advanced cam indexer features torsion clutch for the protection against overload. - Delivery Section

Automatic pallet delivery system achieves non-stop feeding, with machine height increased by 300mm.

MWZ 1300Nii automatic flatbed die cutter can be used as cardboard cutting machine and corrugated die cutting machine to cut cardboards and corrugated boards for manufacturers of cardboard boxes and packaging boxes.