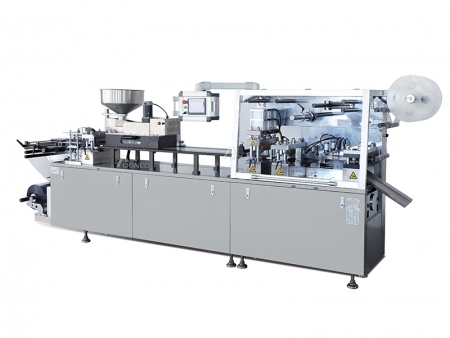

DPP-250LL Pharmaceutical Blister Packaging Machine

For principle of DPP-250LL pharmaceutical blister packaging machine, transparent plastic film or sheet form blister and methods such as heat sealing or adhesive sealing are used to seal the product between blister and the base plate. Based on many years of manufacturing experience and reference to the original Italian prototype, this product adopts many latest technologies at domestic and abroad. So it reaches advanced level in international level due to its outstanding performance, creative concept and novel shape. This product can realize 100 percent synchronization for feeding, filling, sealing, batch number printing, indentification and metering. With positive pressure and smooth process, production process is obvious and easy to clean up. Of course, the whole production process is in full compliance with the GMP requirements.

Detailed Specifications| Punch frequency | 15~35 times/min |

| Productivity | 40,000-100,000 Pcs/h |

| Max. forming area and forming depth | 120x240x26mm |

| Range of adjustable distance | 30~120mm |

| Width and thickness of PVC & PTP | PVC:0.15~0.45X250mm PTP:0.02~0.03x250mm |

| Power supply | 380V 50HZ |

| Power | 6KW |

| Air consumption | ≥0.38m3/min |

| Cooling of mold | Tap water or cycling water, 60L/H |

| Dimension (LxWxH) | 3650x825x1735mm |

| Dimension of packaging case (LxWxH) | 3800x1050x1900mm |

| Weight | 1500kg |

Undoubtedly, DPP-250LL pharmaceutical blister packaging machine possesses many powerful performances. In the first place, cold punching positive-pressure molding is adopted so blister is uniform. Secondly, man-machine touch screen operator interface is applied, key is sensitive and menu setting is reasonable as well. Besides that, integration of micro-computer technology, automation technology and communication technology is realized by PLC programmable controller, thus greatly improving automation degree. In most domestic machines, adjustments for traction and station are put at the front and rear end. However, they are all placed at the front of DPP-250LL pharmaceutical blister packaging machine to make the design more user-friendly and reasonable. According to customers' requirements, automatic missing piece detection and automatic waste picking device can be added to reduce manual link and increase production efficiency. Last but not least, with modular structure station, this product allows accurate positioning and easy replacement of mold.

We are a specialized pharmaceutical blister packaging machine manufacturer in China. We offer a broad range of products, including capsule sorting polisher, fully automatic capsule filler machine, bottom homogenizing vacuum emulsifier equipment and so on.