Concealed Roof Panel Forming Machine

Concealed RoofPanel Forming Machine

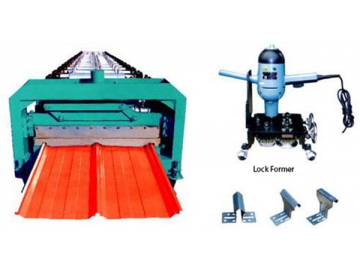

As a kind of metal forming machine, our concealed roof panelforming machine is made up of a feed leading table, main formingmachine, cutting device, hydraulic station, computer control system etc.

Optional devices include a manual uncoiler and a hydraulic uncoiler.

Our concealed roof panel forming machine can be designed and manufacturedaccording to customers' special requirements.

Product Features

1. The product ofour concealed roofpanel forming machine has solved many problems existing in generalroof panels, such as leakage.

2. Unlike traditional bolt connection,it uses 45 degrees occluding installation, resulting in a better water-proofeffect.

3. Our concealed roof panel formingmachine can produce metal material, which has high wave crest, great intensity,reliable installation, and better waterproof performance.

4. It is lower in cost andlightweight.

MainComponents

Our concealed roof panel forming machine consists of amanual decoiler, feeding platform, main molding core, shearing mechanism,hydraulic station, computer control cabinet, high precision counter, and drivensystem protective covering panel supporting table.

Flow Chart

Decoiling-active feeding –Roll forming-measuring length-cutting tolength-product to stand

Technical Parameters

| Item | Description |

| Material Width | |

| Material Thickness | |

| Material | PPGI HDGI |

| Yield Stress | 235Mpa |

| Material of Roller | 45# steel plant hard chromium |

| Diameter of Shaft | |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 5.5kw |

| Hydraulic Power | 4kw |

| Stand | 20-26 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 6 |

| Decoiler | 5 tons manual or hydraulic |

Machine Placement and Operator

The concealed roof panel forming machine should be placed on an evencement floor and lifted by a lifting device with a lifting capacity not lessthan five tons. It requires space forstoring materials and laying the machine and room to operate. The forming machine requires one operator andone porter. The temperature in the workspace should be no less than

Concealed Roof PanelForming Machine YX76-380-760

| Item | Description |

| Material Width: | |

| Material Thickness | |

| Material | PPGI HDGI |

| Yield Stress | 235Mpa |

| Material of Roller | 45# steel plant hard chromium |

| Diameter of Shaft | |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 5.5kw |

| Hydraulic Power | 4kw |

| Stand | 22 |

| Host Dimension | 11*1.3* |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8 |

| Decoiler | 5 tons manual or hydraulic |

Concealed Roof Panel FormingMachine YX51-410-820

| Item | Description |

| Material Width: | |

| Material Thickness | |

| Material | PPGI HDGI |

| Yield Stress | 235Mpa |

| Material of Roller | 45# steel plant hard chromium |

| Diameter of Shaft | |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 5.5kw |

| Hydraulic Power | 4kw |

| Stand | 20 |

| Host Dimension | 10.3*1.3* |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8 |

| Decoiler | 5 tons manual or hydraulic |

Haide Machinery Manufacturing Company is a major manufacturer and supplier ofconcealed roof panel forming machines based in