Stainless Steel Pipe

Type: round or square & rectangular (CHS, SHS, RHS)

Standards:

GB/T14976-2002, GB/T14975-2002, GB13296-2007, GB5310-1995

ASTM/ASME A/SA213

Seamless (Ferritic) and Austenitic Alloy-Steel Boiler, Super heater, and Heat-exchanger Tubes

ASTM/ASME A/SA269

Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ASTM/ASME A312/A312M for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes.

ASTM A511 for Seamless Stainless Steel Mechanical Tubing

ASTM/ASME A999 for General Requirements for Alloy and Stainless Steel Pipe

ASTM /ASME A358 Electric-Fusion-Welded Austenitic Chromium-Nickel Stainless Steel Pipe for High-Temperature Service and General Applications

ASTMA790, ASTMA789 ASTMA376, ASTMB677. ASTMB423, ASTMB167

JIS G3459, Japanese Industrial Stainless Steel Pipe

DIN17456, DIN17458

EN10216-5 Seamless steel tubes for pressure purpose.

GOST9941-80, GOST9941-81

For seamless cold and warm-deformed tubes made from corrosion-resistant steel of general purpose

Grade:

304, 0Cr18Ni9, TP304, SUS304, UNS30400, 304L, 00Cr19Ni10, TP304L, SUS304L, UNS30403 TP304/304L, TP316/316L, TP321, TP310S, TP304LN, TP347H, TP316LN, TP316Ti, TP309, TP317, 904L and Duplex(S31803) SUS 304TB, SUS304HTB, SUS304LTB, SUS310TB, SUS310STB, SUS316TB, SUS316LTB, SUS316TiTB, SUS317TB, SUS317LTB, SUS321TB, SUS321HTB, SUS347TB, SUS347HTB 08Х17Т, 08Х13, 12Х13, 12Х17, 15Х25Т, 04Х18Н10, 08Х20Н14С2, 10Х17Н13М2Т, 08Х18Н12Б, 10Х23Н18, 08Х18Н10, 08Х18Н10Т, 08Х18Н12Т, 08Х17Н15М3Т, 12Х18Н10Т, 12Х18Н12Т, 12Х18Н9, 17Х18Н9, 08Х22Н6Т588, 05ХН28МДТ

1.4307, 1.4306, 1.4301, 1.4541, 1.4404, 1.4401, 1.4571;

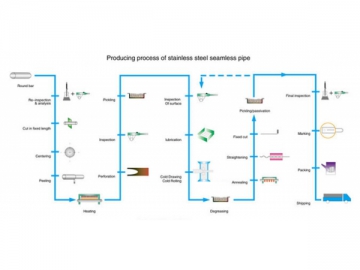

Production Method: cold drawing, precision rolling

O.D.: 12-800mm

Thicknesses: 2-30mm

Schedule: 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S, acc. to ANSI B36.19

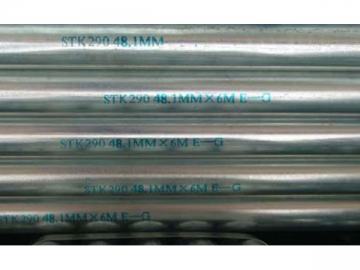

Length: 3-11.8m according to customer's request.

Surface: Annealed/Pickled/Polished.

Packing: Wooded crate, or in bundle wrapper by knitting

Delivery time: Within about 30-45 days

Payment: 30% deposit before manufacture, balance before shipment; Or LC at sight.

Certificate: PED, DNV, ABS, KR, LR, GL, RS, CE, ISO9001

Specialty and advantages:

The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill.

We have advanced NDT equipment for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, SGS, etc, also can be provided according to customers’ requirements,

Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

The tolerance control we use is D4/T4 ( /-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

In order to keep the inside surface of pipe clean and make it free from deburring, our company develops the unique and special technology --- Sponge Washing with high pressure.

We have complete after-sale service to deal with the problems in time.