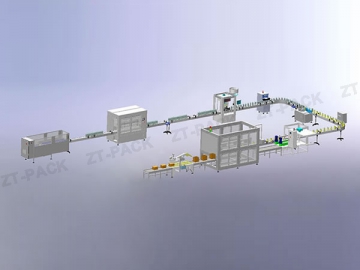

Corrosive Liquid Packaging Line

Request a Quote

The corrosive liquid packaging line is used to fill bottles with a capacity under 5000ml. This packaging line is a complete production line consisting of an automatic bottle opener, filling machine, capping machine and self-adhesive labeling machine. It also carries out box packing and sealing. This liquid packing line is suitable for strong acid and strong base, bleach, Clorox® disinfecting bleach and some other corrosive liquid with low viscosity, requiring pilfer proof cap.

Features

- Three people (one operator and two assistants) are required operating this corrosive liquid packaging line.

- The highly efficient bottle unscrambler is applicable for flat and round bottles. The size of suitable bottles is adjustable. The bottles dropping from the line will be sent back to the conveyor while workers responsible for product settling will inform operators about unfilled bottles.

- The servo volumetric piston filling machine features a high precision. The nozzles will automatically adapt to various bottles and reduce bubble generation.

- The rotary capping machine features a 100% pass rate by rejecting uneven or broken caps.

- The automatic unpacking and sealing machine features an easy operation, thus increasing the production speed.

Technical Parameters

| Capacity | 50ml -100ml≤6000 b/h; 500ml≤5000 b/h; 1000ml≤4500 b/h |

| Suitable bottle | round bottle Φ40-100mm, height 80-280 mm Flat bottle (40-100mm)*(40-100mm)*(80-280mm) (LxWxH) |

| Neck diameter | ≥φ25mm |

| Filling range | 100-5000ml |

| Accuracy | (200ml)±1%; (200ml-1000ml)±0.5% |

| Air pressure | 0.6〜0.8 MPA |

| Power source | 〜380V, 50HZ |

| Production line height | 900mm±50mm |

| Bottle feed direction | from left to right |

Suitable bottles