Plastic Pulverizer

LHD series plastic pulverizer is mainly used for grinding thermosensitive materials (Mohs hardness: 3), including PVC, PE, PET, PC, LDPE, HDPE, EVA, etc., which feature with high elasticity and impact-resistance. Just because this plastic pulverizer is widely used for pulverizing PVC and PE, it also called as PVC pulverizer or PE pulverizer.

This impact mill is extensively used in fields like powder spraying, plastic extrusion, etc.

| Data \ Model | Main power(kw) | Feed size(mm) | Fineness | Capacity |

| 45 | <5mm | 20-500mesh | 50-1000kg/h | |

| 90 | <5mm | 20-500mesh | 100-2200kg/h |

- Low energy consumption and no temperature raising during pulverizing process;

- The plastic pulverizer can produce powders in different fineness by adjusting the distance between rotor disc and stator disc.

- If equipped with vibrating screen and air classifier, our plastic pulverizer will be able to produce ultra-fine powders. Unqualified powders will return to milling chamber for second time grinding.

- Negative pressure operation and positive pressure operation, normal temperature grinding and cryogenic grinding, etc. are all available for grinding different kinds of materials.

- Stable mechanical performance, simple operation and convenient maintenance.

Firstly feed material into grinding chamber, and then they will be pulverized under the shearing force generated between high speed rotary rotor disc and stator disc.

Finished powders will be sent to collection system.

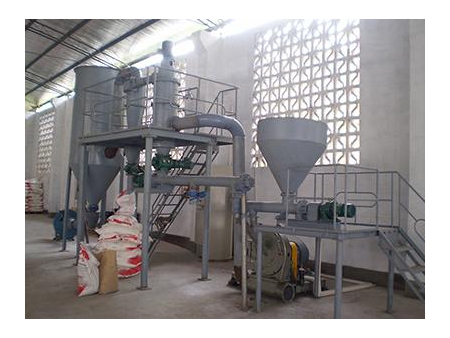

1. Feeding system

2. Main machine of grinding mill

3. Cyclonic collector

4. Pulsed dust collector

5. Induced draft fan

1. Feeding system

2. Plastic pulverizing system

3. Cyclonic collector

4. Vibrating screen

5. Pulsed dust collector

6. Induced draft fan

1. Material feeding system

2. Plastic pulverizing system

3. Screw conveyor for material feed back

4. Classification system

5. Pulsed dust collector

6. Induced draft fan

1. Pre-cooling system (also functioned as screw conveyor for feeding material)

2. Powder grinding system

3. Cyclonic collector

4. Induced draft fan

5. Pulse bag type dust collector