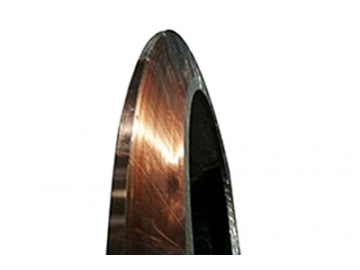

CuMn12Ni2 Resistance Alloy

Introduction

The main components of this resistance manganese-copper alloy (CuMn12Ni2) are copper and manganese, which has the same resistivity and similar temperature coefficient of resistance with the constantane. Compared with constantane resistance alloy, copper manganese resistance alloy has advantage of low cost, for having no nickel of high price. But its oxidation resistance performance is poor than constantane. It can replace the constantane resistance alloy in many applications. Manganese copper has low temperature coefficient of resistance, wide operating temperature range, good processing performance, good solderability and extremely low thermal electromotive force against copper.

| Type | Size | ||

| Round wire | D=0.03mm~8mm | ||

| Flat wire | W=0.4~40 | T=0.03~2.9mm | |

| Strip | W=8~200mm | T=0.1~3.0 | |

| Foil | W=6~120mm | T=0.003~0.1 | |

| Rod | Dia=8~100mm | L=50~1000 | |

Application

CuMn12Ni2 resistance alloy is mainly used to produce precision wire wound resistor, potentiometer, shunt and other electrical and electronic elements.

| Nickel | 2~3 |

| Manganese | 11~13 |

| Copper | Balance |

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation (%) | Density (g/cm3) | Resistivity (20℃) (Ω・mm2/m) | Resistance temperature coefficient (20℃~600℃) 10-5/℃ | Conductivity (20℃) (WmK) | Electromotive force against copper (μV/℃ ) (0~100℃) | Expansion coefficient (20 ℃- 400℃) x10-6/K | Expansion coefficient (20 ℃- 100℃) x10-6/K | Melting point (℃) | Max.operating temperature (℃) | Magnetism |

| 180 | 390 | 15 | 8.44 | 0.47 | -3~20 | 40 | 1 | 18 | 0.41 | 960 | 5~45 | Non-magnetism |

| Atmospheric corrosion resistance at 20℃ | Corrosion resistance at maximum operating temperature | ||||

| Air and other oxygen-containing gases | oxygen-containing gas | Sulfurous gas (oxidizability) | Sulfurous gas (reducibility) | Carburization | |

| Good | Good | Good | Good | Poor | Good |

Index

alloy strip, resistance alloy