85%-92% Concentration Methylal Plant

Request a Quote

85%-92% concentration process is a common methylal production process. Helipont improved this process to decrease methanol and formaldehyde consumption, and control the COD concentration in the waste water from the bottom of the reaction tower to remain lower than 200ppm.

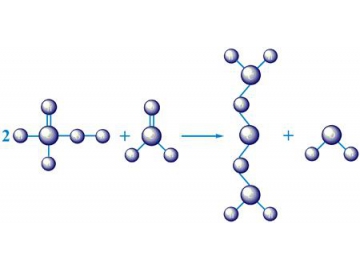

Flow chart

Main Equipment for 99.5% Concentration Process

- Reaction tower

- Reboiler

- Mixer

- Pre-reactor

- Knapsack reactor

- Condenser

- Reflux drum

- Rectifying tower

- Mix formaldehyde and methanol as a certain mass ratio to get methylal.

- Rectify the methylal.

Annotation: for more information about the production process, please do not hesitate to contact us.

Consumption index| Item | Consumption quota | Remarks |

| Raw material and auxiliary material | ||

| Formaldehyde(37%) | 1.04t/t | |

| methanol(99.5%) | 0.86 t/t | |

| Utilities | ||

| Industrial feeding water t≤25℃ | Intermittent flushing | |

| Circulating water t≤32℃,△t=8℃, Circulating quantity per hour | 75 t/t | |

| Power(380V) | 50kWh/t | |

| Low pressure steam P=0.25MPa(G) | 750kg/t | |

Projects Were Work on