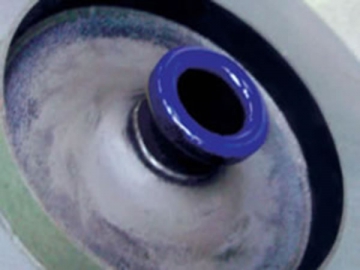

Glass Lined Multi-tube Heat Exchanger

There are boiling, condensation, and other heat transfer processes in the production lines in the chemical and pharmaceutical industries. These require choosing appropriate equipment according to the type of liquid, the operating conditions, and other factors, so as to meet the production needs.

The glass lined multi-tube heat exchanger we provide is equipped with multiple glass-lined steel tubes. Due to the advanced technology introduced from Japan, our shell and tube heat exchanger enjoys high heat transfer efficiency which is several times that of ordinary plate heat exchanger. Also, it overcomes the latter's shortcomings of slow flow rate, easy enamel explosion, and intolerance to ultimate vacuum.

Features

1. High Corrosion Resistance

Manufactured from glass lined steel, the multi-tube heat exchanger is corrosion-resistant and of long service life.

2. Easy to Clean

The enamel imported from Japan is adopted. It offers excellent anti-stick properties and makes the internal surface of the multi-tube heat exchanger smooth and thus easy to clean.

3. Small Footprint

Compared with other glass lined condensers, this multi-tube condenser boasts smaller heat exchange area per unit, so it is more compact and economical.

| Glass Lined Shell and Tube Heat Exchanger | ||

| Design pressure | Shell | 0.59MPa |

| Tube | FV-0.59MPa | |

| Design temperature | Shell | 180℃ (453K) |

| Tube | 180℃ (453K) | |

| Allowed thermal shock | △t=100℃ (100K) | |

| Overall heat transfer coefficient | 150-350kcal/m2·h·℃ (170-400W/m2·K) | |

| Pinhole test | D.C.10000V electric test | |

| Hydrostatic test | 0.59MPa | |

| Air tight test | According to customer requirements | |