Polycrystalline Diamond Composites (PDC)

Request a Quote

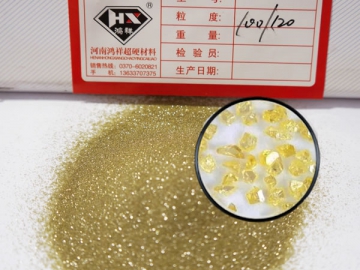

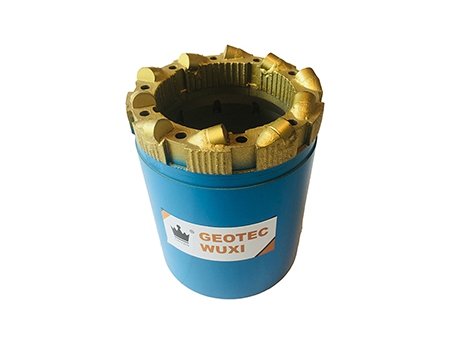

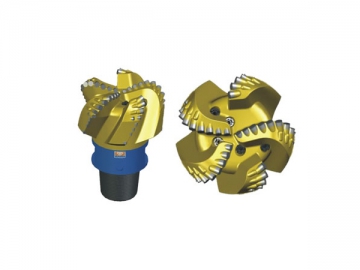

A full range for PDC cutters designed for use as mining bits, oil drilling bits and gas drilling bits are manufactured via state-of-the-art sintering processes. The PDC (short for polycrystalline diamond composite) consists of layers of polycrystalline diamond fused to a cemented carbide substrate at high temperatures and pressure.

Features of PDC

PDC cutters combine the hardness and abrasion resistance of diamond with the impact resistance of tungsten carbide, providing a faster, more durable and cost effective drilling.

Polycrystalline Diamond Composite Uses

PCD is most often designed for oil and gas drilling, and mining bits.

| Product Number | Diameter (D) (mm) | Height (T) (mm) | Diamond Thickness (t) (mm) | Diamond Chamfer (mm) | Carbide Chamfer |

| 1308 | 13.44±0.03 | 8.00±0.10 | 2.30±0.20 | 0.30±0.10 | 0.5x45° |

| 1313 | 13.44±0.03 | 13.20±0.10 | 2.30±0.20 | 0.30±0.10 | 0.5x45° |

| 1608 | 15.88/16.00 ± 0.03 | 8.00±0.10 | 2.30±0.20 | 0.30±0.10 | 0.5x45° |

| 1613 | 15.88/16.00 ± 0.03 | 13.20±0.10 | 2.30±0.20 | 0.30±0.10 | 0.5x45° |

| 1908 | 19.05±0.05 | 8.00±0.10 | 2.30±0.20 | 0.30±0.10 | 0.5x45° |

| 1913 | 19.05±0.05 | 13.20±0.10 | 2.30±0.20 | 0.30±0.10 | 0.5x45° |

| 1916 | 19.05±0.05 | 16.31±0.10 | 2.30±0.20 | 0.30±0.10 | 0.5x45° |

Related products

Send Message

Most Recent

More

Other Products

Videos

.jpg)