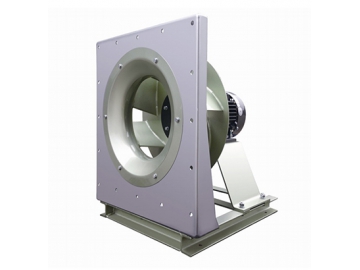

Centrifugal Fan

Centrifugal fans of 4-72 are usually used in two ways. One is for the indoor ventilation and air exchange of large scale factories or buildings. The other is to transport air or other non-flammable, non-explosive, non-volatile, non-corrosive and harmless gas. Outlet air from our fans is free from sticky particles, dust and particles no more than 150mg/m3. Temperature of the gas is no more than 80℃.

Centrifugal fan of F4-72 is produced from stainless steel, glass fiber reinforced plastics or other corrosion resistant materials.

Model

Model A: the motor is outside-mounted, this model can work for 30 min at 280℃. So it can be used for both normal ventilation and fire emergencies.

Model B: The motor is built-in. Model B centrifugal fan is a versatile ventilator.

Model 11: A two speed motor is adopted. This model can work on variable working conditions.

Feature of centrifugal fan

1. The centrifugal fan consists of low-noise forward-leaning multi-blade centrifugal impellers, quality bearing and central spindle. The box shell comes in a sound absorption structure, and could be made of color steel plate, hot dip galvanized steel plate, and painted cold-rolled steel sheet.

- Parameter of 4-72-3A Centrifugal Fan

- Parameter of 4-72-12C Centrifugal Fan

| 4-72No2.8A, 3.2A, 3.6A Centrifugal Fan Selection Guide | |||||||||||||

| Model | Transmission Type | Rotating Speed (r/min) | NO. | Air Flow Rate (m3/h) | Total Pressure (Pa) | Internal Efficiency (%) | Internal Power (kW) | Required Power (kW) | Electromotor | 4 foundation bolts (GB799-76) | 4 nuts (GB799-76) | 4 gaskets (GB96-85) | |

| Model | Power (kW) | ||||||||||||

| 2.8 | A | 2900 | 1 | 1131 | 994 | 69.3 | 0.45 | 0.67 | Y90S-2 (B35) | 1.5 | M8*220 | M8 | 8 |

| 2 | 1310 | 966 | 73.2 | 0.48 | 0.72 | ||||||||

| 3 | 1480 | 933 | 75.5 | 0.51 | 0.71 | ||||||||

| 4 | 1659 | 887 | 76.8 | 0.53 | 0.74 | ||||||||

| 5 | 1828 | 835 | 76.9 | 0.55 | 0.77 | ||||||||

| 6 | 2007 | 770 | 75.6 | 0.57 | 0.79 | ||||||||

| 7 | 2177 | 702 | 73.2 | 0.58 | 0.81 | ||||||||

| 8 | 2356 | 606 | 69.3 | 0.57 | 0.8 | ||||||||

| 3.2 | A | 2900 | 1 | 1688 | 1300 | 69.3 | 0.88 | 1.23 | Y90L-2 (B35) | 2.2 | M8*220 | M8 | 8 |

| 2 | 1955 | 1263 | 73.2 | 0.93 | 1.31 | ||||||||

| 3 | 2209 | 1220 | 75.5 | 0.99 | 1.38 | ||||||||

| 4 | 2476 | 1160 | 76.8 | 1.03 | 1.34 | ||||||||

| 5 | 2729 | 1091 | 76.9 | 1.07 | 1.39 | ||||||||

| 6 | 2996 | 1006 | 75.6 | 1.1 | 1.43 | ||||||||

| 7 | 3250 | 918 | 73.2 | 1.13 | 1.47 | ||||||||

| 8 | 3517 | 792 | 69.3 | 1.11 | 1.45 | ||||||||

| 3.2 | A | 1450 | 1 | 844 | 324 | 69.3 | 0.11 | 0.16 | Y90S-4 (B35) | 1.1 | M8*220 | M8 | 8 |

| 2 | 978 | 315 | 73.2 | 0.12 | 0.17 | ||||||||

| 3 | 1104 | 304 | 75.5 | 0.12 | 0.19 | ||||||||

| 4 | 1238 | 289 | 76.8 | 0.13 | 0.19 | ||||||||

| 5 | 1365 | 272 | 76.9 | 0.13 | 0.2 | ||||||||

| 6 | 1498 | 251 | 75.6 | 0.14 | 0.21 | ||||||||

| 7 | 1625 | 229 | 73.2 | 0.14 | 0.21 | ||||||||

| 8 | 1758 | 198 | 69.3 | 0.14 | 0.21 | ||||||||

| 3.6 | A | 2900 | 1 | 2664 | 1578 | 74.2 | 1.56 | 2.03 | Y100L-2 (B35) | 3 | M10*220 | M10 | 10 |

| 2 | 3045 | 1531 | 77.8 | 1.65 | 2.15 | ||||||||

| 3 | 3405 | 1481 | 80.3 | 1.73 | 2.25 | ||||||||

| 4 | 3786 | 1419 | 82.1 | 1.81 | 2.35 | ||||||||

| 5 | 4146 | 1343 | 82.6 | 1.86 | 2.42 | ||||||||

| 6 | 4527 | 1256 | 81.8 | 1.92 | 2.5 | ||||||||

| 7 | 4887 | 1144 | 79.5 | 1.95 | 2.53 | ||||||||

| 8 | 5268 | 989 | 74.3 | 1.94 | 2.52 | ||||||||